Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

With our carbon nanotechology platform as a base, we develop material solutions for use in the hydrogen industry. Like a coated nanostructure that acts as a scaffold for iridium catalysts.

Currently, we focus on improving the electrochemical cell in PEM electrolyzers and fuel cells. The cell enables the conversion of electricity into hydrogen and vice versa. Thus, it’s a key component in storing and transmitting renewable energy and decarbonizing industry, transportation, and heating.

Smoltek Hydrogen’s PTE (porous transport electrode) technology reduces iridium usage by 95%, to just 0.1 mg/cm², while maintaining equivalent current density and durability. Our nanofiber deposition process creates a surface area that is 30 times larger, ensuring that nearly all of the catalyst material actively participates in the reaction. This breakthrough eliminates the iridium scarcity that limits production volumes and cost targets.

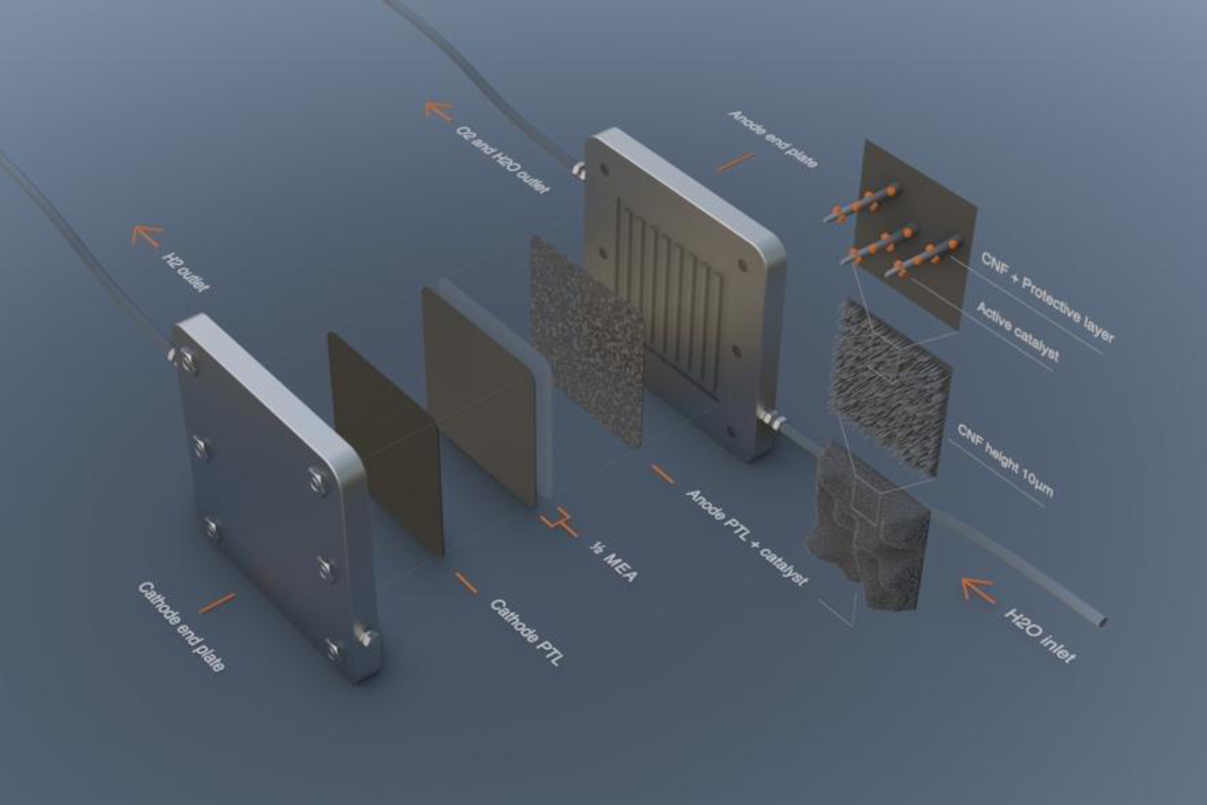

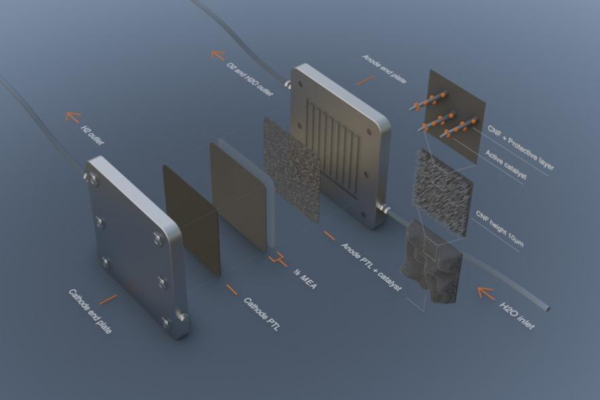

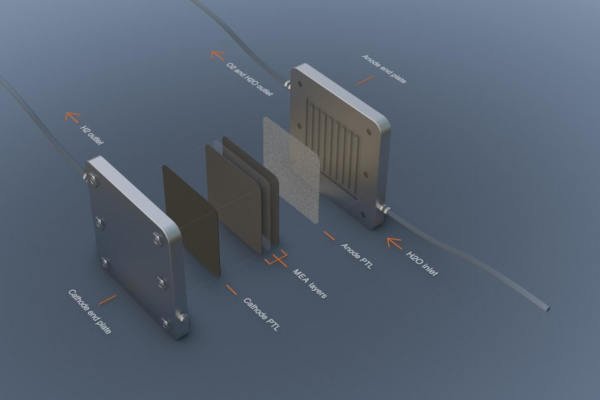

The Smoltek PTE* uses coated (corrosion protected) carbon nanofibers (CNFs) as catalyst support applied directly on the PTL substrate (a method called Catalyst Coated Substrate, or CCS), making all the extremely expensive iridium catalysts come in full contact with the MEA. The result is that the need for iridium particles can decrease significantly – we have already showed that our PTE can produce the same amount of hydrogen with only 0.1−0.2 mg iridium/cm2 as a conventional cell that uses 2.0−2.5 mg iridium/cm2.

* The Smoltek PTE combines the anode PTL with catalyst, thus reducing the MEA layer to just ½ MEA. As seen in the different zoom-ins, the porous PTL is filled with carbon nanofibers (CNFs) that penetrate the ½ MEA, enabling all of the iridium catalysts to make contact with the MEA.

Smoltek’s technology offers a solution to this problem. It enables the manufacture of a new and more efficient PTE for PEM electrolyzers based on our patent protected carbon nanotechnology that creates a three-dimensional surface structure on the anode side’s PTL layer.

The technology enables all iridium catalyst particles to come into contact with the membrane, thanks to the fact the particles are deposited on the nanostructure which is directly in contact with the metallic PTL surface. Thereby, the expensive catalyst particles are fully utilized; thus, the iridium catalyst load in the cell can be reduced by up to 95 percent. This is particularly important as the supply of iridium and platinum are considered critical, i.e. the future demand for these materials cannot be met with certainty, and the reduced supply risks lead to increased production costs for green hydrogen further.

Smoltek’s nanostructure also increases the surface area of the electrode (the one in contact with the membrane). This means that more particles can be placed on a given surface, which in turn can reduce the electrolyzer in size by two to three times while maintaining capacity. A reduced-size means, among other things, smaller investments and lower maintenance and material costs.

Don’t hesitate to contact us with your questions.

Whitepaper

A deep dive into Smoltek’s electrolyzer technology – get your free copy from Smoltek. This is not a marketing brochure, but a 15-page technical whitepaper authored by our nanotechnology experts. Learn about how CVD-grown carbon nanofibers can revolutionize hydrogen production, improve catalyst efficiency in PEM electrolyzers, and enable more efficient renewable energy storage.

Download