Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

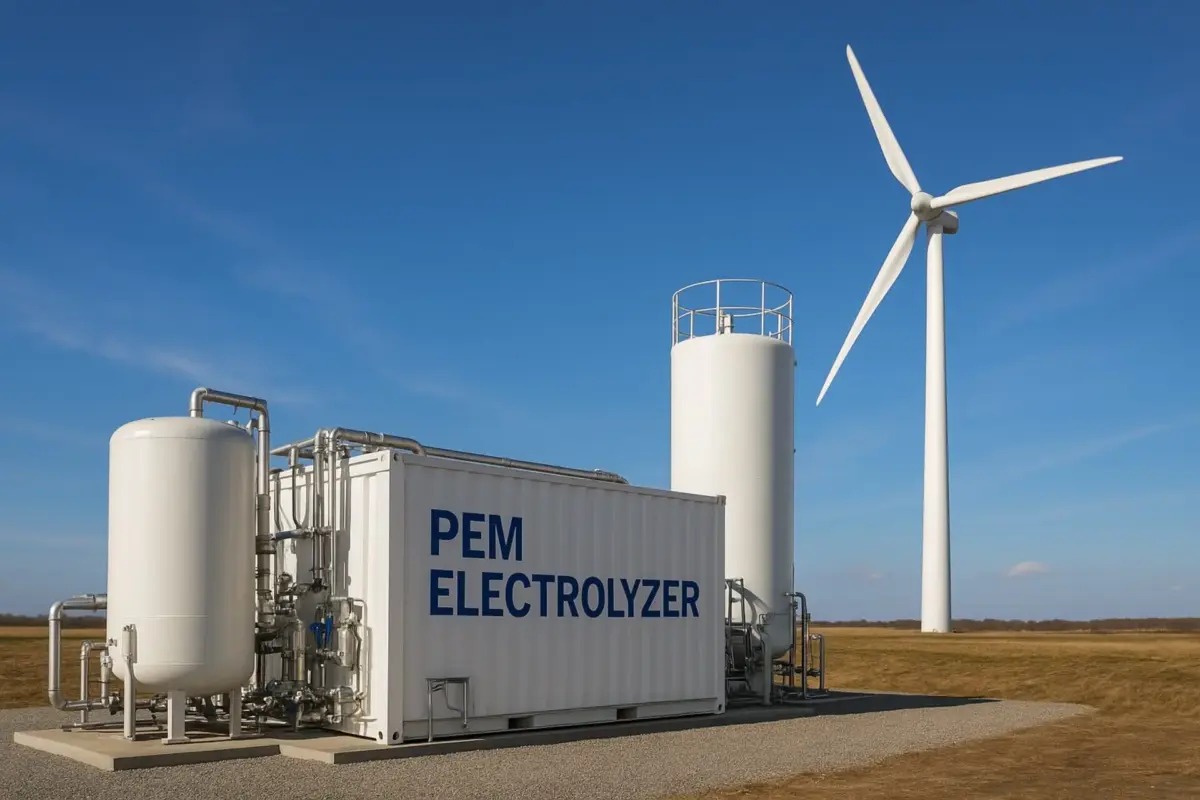

Smoltek hydrogen is paving the way for a sustainable future as we are making production of green hydrogen viable. By introducing a porous transport electrode (PTE) for PEM electrolyzers that increases the active surface area by 30 times and reduces the need for iridium by up to 95 percent, while maintaining high performance, we are enabling the scale-up of next generation PEM electolyzers.

Smoltek Hydrogen can create a highly attractive market position based on substantial cost leadership as we have developed a solution to the most critical obstacle limiting the large-scale adoption of green hydrogen: the extreme scarcity and high cost of iridium catalyst used in PEM electrolyzers.

Our innovative PTE technology succeeds where competitors have struggled in trying to refine the coating of the membrane (CCM). By taking a Catalyst Coated Substrate (CCS) approach – coating of the metallic substrate instead of the plastic membrane – we now have the solution for cost-effective fossil-free hydrogen production.

Iridium’s scarcity and cost pose a major barrier to scaling green hydrogen production. Global output is limited to just 7–8 tons per year—enough for only 4–5 GW of PEM electrolyzer capacity at today’s usage rates (1–2 mg/cm²). That’s just 2% of projected 2030 demand.

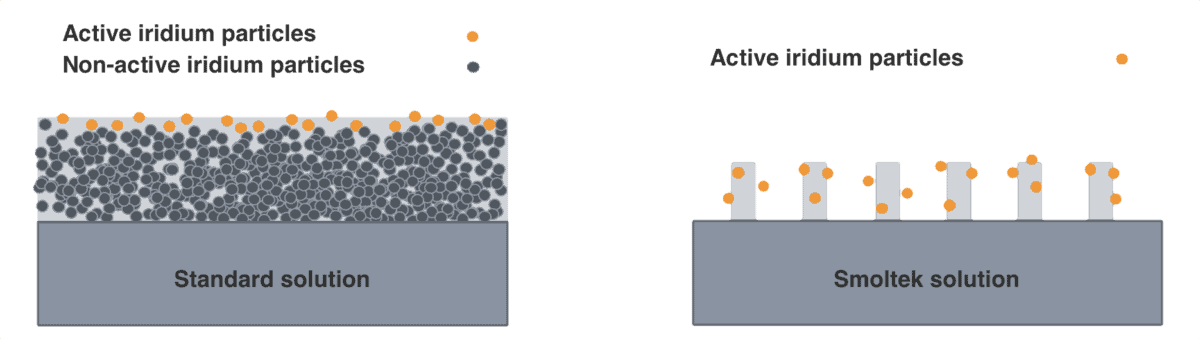

Conventional Catalyst Coated Membranes (CCM) waste much of this precious metal, as only surface atoms are active while the rest remain unused. At 2 mg/cm², iridium costs reach $60 million per gigawatt. Reducing usage to 0.1 mg/cm² would cut that to just $3 million—a critical step toward economic viability.

Despite years of research, industry has stalled at 0.5 mg/cm²—still five times above the target.

Smoltek Hydrogen offers a solution for the porous transport electrode (PTE): a Catalyst Coated Substrate (CCS) using our proprietary carbon nanofiber technology. By increasing the active surface area 30-fold, we enable nearly full catalyst utilization and achieve the 0.1 mg/cm² milestone—unlocking scalable, cost-effective green hydrogen.

Smoltek Hydrogen has successfully reduced the loading of Ir-based catalyst to 0.1 mg iridium/cm2, without compromising the overall performance of the PEM electolyzer. The reduction of iridium is critical in order to enable global mass manufacturing targets for green hydrogen production using PEM electrolysis.

Key features of Smoltek Hydrogen’s Porous Transport Electrode (PTE):

Electric heavy-duty vehicles are the key to fossil-free transport. When batteries would not provide a long enough range, fuel cells are the alternative. The vehicle is loaded with hydrogen, which the fuel cell transfers into electricity. This will be used for heavy-duty trucks, coaches, long-range passenger vehicles, and trains.

For long distances, heavy marine transports synthetic fuel is a convenient way to make the transports green. Existing combustion engines are run on synthetic fuels produced from green H2. Also, biofuels, lithium-ion batteries, and fuel cells will be used to make the sector fossil-free. Still, synthetic fuels are considered most attractive, given that the cost of producing hydrogen can be reduced.

Ammonia is the second most commonly produced chemical in the world, and it is derived from hydrogen. More than 80 percent is used as feedstock for fertilizer. The rest are used in making paint, plastic, textiles, explosives, and other chemicals. Ammonia production in 2018 generated around 500 million tons of carbon dioxide, where a large part comes from hydrogen produced by steam methane reforming. Making this from green hydrogen instead implies an immense growth of the electrolyzer market.

New steel works are being built all around Europe, something that has not happened for hundreds of years. The new steelworks will be using green hydrogen instead of fossil gas. Each ton of steel produced today is estimated to emit 2.2 tons of carbon dioxide—equating to about 11 percent of global carbon dioxide emissions. In Sweden, two well-known examples are the HYBRIT project run by SSAB, LKAB, and Vattenfall, and H2 Green Steel, a new ambitious company building new steelworks in Sweden and Iberia. Similar projects are seen, for instance, in Germany. For each new steelworks, a new large-scale hydrogen plant is being built.

Green hydrogen can be used for high-grade industrial heating in, for example, the cement industry, which accounts for 8 percent of global carbon dioxide emissions. Emissions can be reduced by a third by using green hydrogen to heat the cement kilns. (The remaining two-thirds come from the chemical reaction that produces cement and must be captured and stored or reduced by other means.)

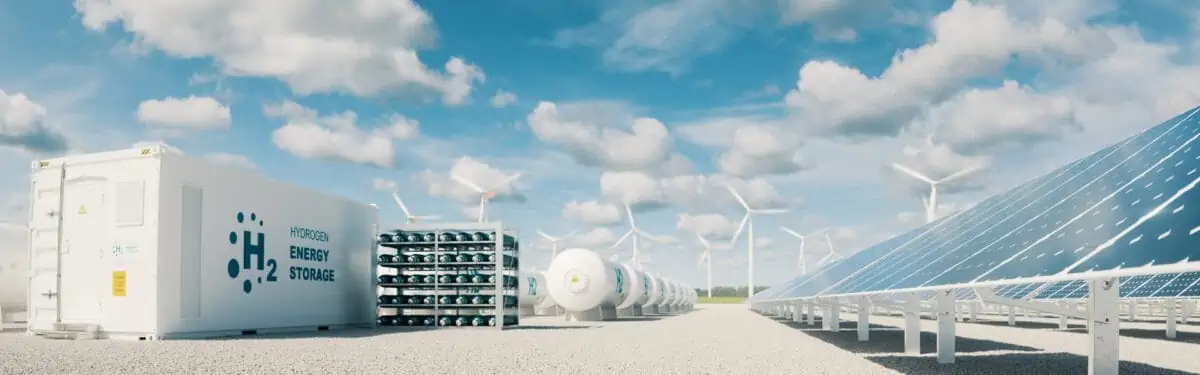

Hydrogen can play a major role in balancing the electrical grid, especially as more variable renewables like solar and wind are added. Electric grids must always balance supply and demand in real time to maintain frequency, otherwise the grid can cause instability or blackouts. To stabilize the grid hydrogen can be used to absorb excess electricity when there’s a surplus, store it, and then release it later when needed. This makes hydrogen a kind of “energy sponge” or long-duration battery for the grid.

Our main objective is to develop robust solutions for industrially relevant catalyst coatings in the energy conversion sector for the future. We build on our experience to scale up nanostructures developed for the semiconductor industry to also incorporate thin films that can catalyze effectively the reactions needed in gas diffusion electrodes for water electrolysis. The goal is to offer our customers superior properties in terms of stability and activity.

Green hydrogen means that electricity from renewable sources is used, like wind, water, and solar energy. The wind and solar power capacity are planned to be built up at a large scale globally to match the demand. The large volume production combined with the technology running down the experience curve indicates an attractive cost per kilowatt from green electricity. For example, wind power is increasingly being produced in large offshore wind farms in the coming decade. Wind power already reaches a lower cost per kilowatt than new nuclear power.