Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Standard Multilayer Ceramic Capacitors (MLCCs), long the industry workhorse, have reached their fundamental miniaturization limits, falling short of the demands for next-generation electronics. Deep Trench Capacitors (DTCs) emerged as an alternative, fabricated using a subtractive process – etching deep, narrow trenches into silicon wafers, which are then filled with complex layers of metal and insulating materials.

However, this subtractive approach faces inherent physical barriers. Uniformly coating these extremely deep and narrow trenches becomes progressively difficult and costly, akin to trying to paint the inside of a very long, thin straw. These manufacturing complexities make DTCs prohibitively expensive for many applications and limit their future scalability, representing a technological dead end.

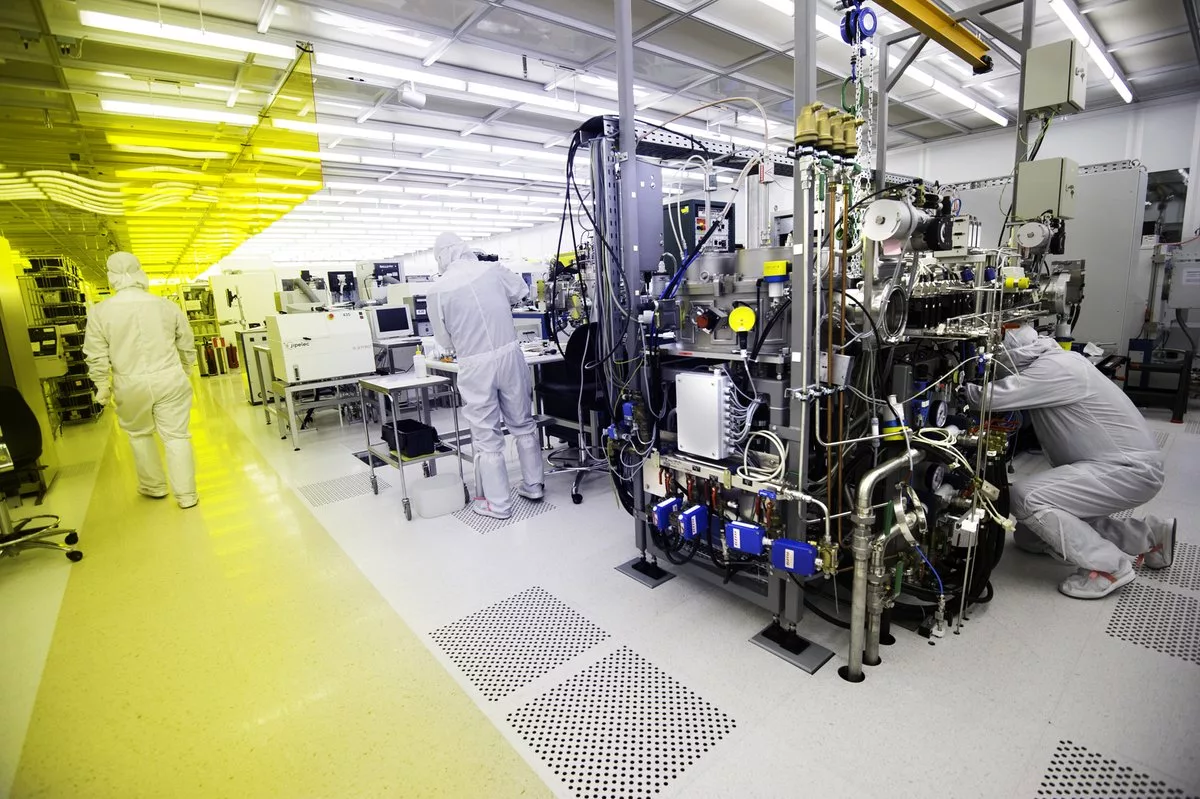

Smoltek’s CNF-MIM technology represents a paradigm shift, moving from the micrometer-scale challenges of conventional methods to precision engineering at the nanometer scale. Instead of carving material away, we employ a fundamentally different additive manufacturing process.

We precisely grow dense arrays of vertically aligned carbon nanofibers (CNFs) – typically tens of nanometers in diameter but micrometers tall – directly onto the substrate. Each fiber acts as a scaffold for the subsequent conformal coating of a Metal-Insulator-Metal (MIM) stack. The crucial advantage lies in the geometry: the combined surface area provided by this dense ”forest” of nanoscale fibers increases the effective surface area by up to 100× compared to the flat footprint they occupy. This massively multiplies the effective electrode surface area, enabling dramatically higher capacitance within an ultra-thin profile.

Critically, this additive nano-scaffolding approach significantly simplifies the manufacturing process compared to the complex multi-step etching and filling required for DTCs. Notably, our process necessitates fewer cycles of expensive and time-consuming Atomic Layer Deposition (ALD) – typically just one ALD step compared to the three or four often needed for DTCs. This inherent process efficiency is expected to significantly reduce front-end production costs compared to DTC technology, offering a compelling economic advantage alongside superior performance potential.