Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Efficient use of iridium can boost green hydrogen production in this decade and Smoltek Hydrogen wants to seize the opportunity by offering a nanostructured porous transport electrode that reduces cost and optimizes use of the critical anode catalyst in PEM electrolysis cells.

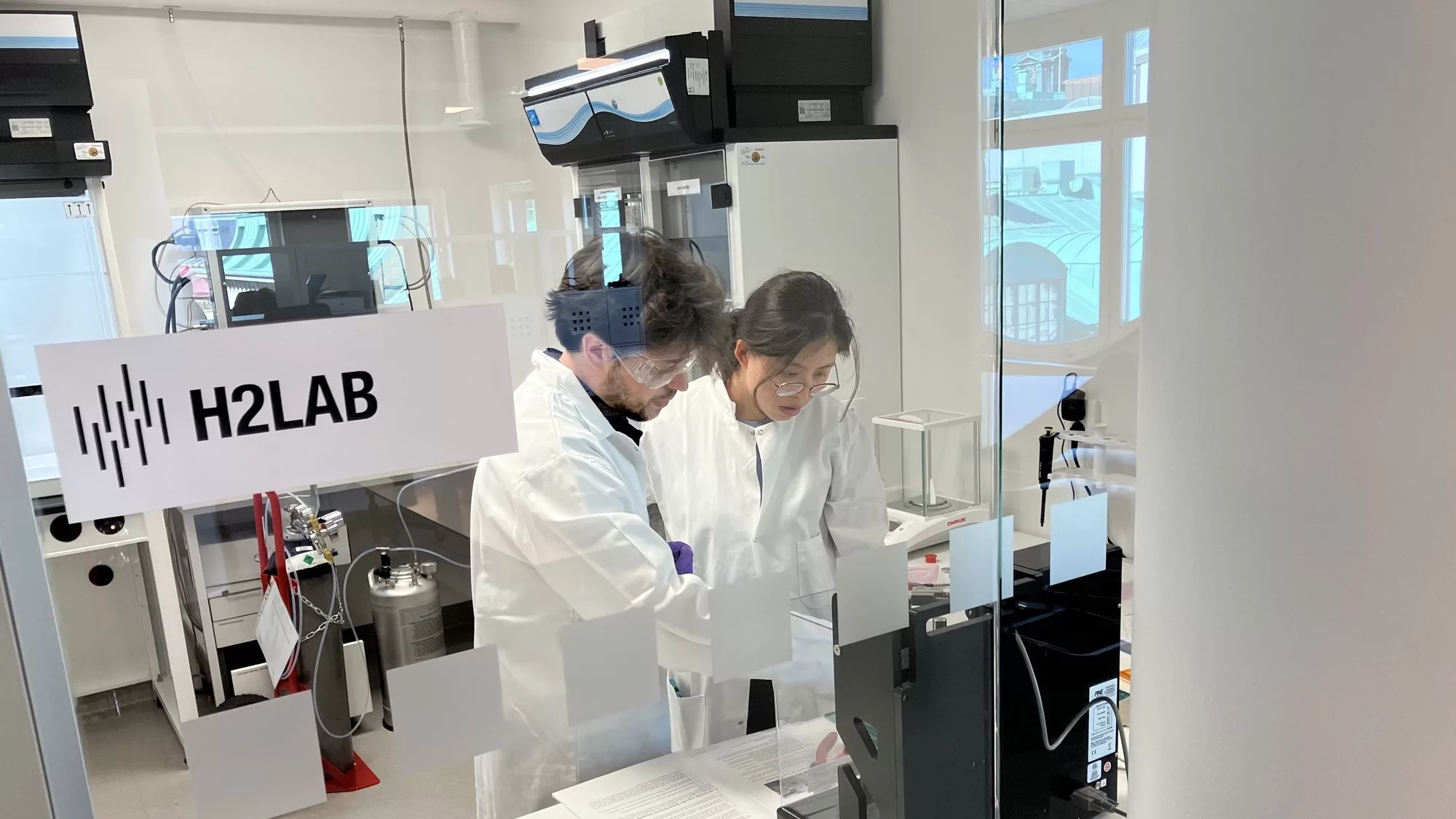

In October 8–12 you can take the opportunity to meet the Smoltek Hydrogen team of experts at the 244th Electrochemical Society Meeting in Gothenburg, Sweden to learn more about our technology, our H2LAB and the road to volume processes for green hydrogen at scale.

We welcome you at the technical exhibit (booth #108) or meet with one of our scientists at the conference: Xin Wen, Bastien Penninckx, Jaime Sanchez, Sankar Sasidharan.

See you in Gothenburg, 8–12 October!

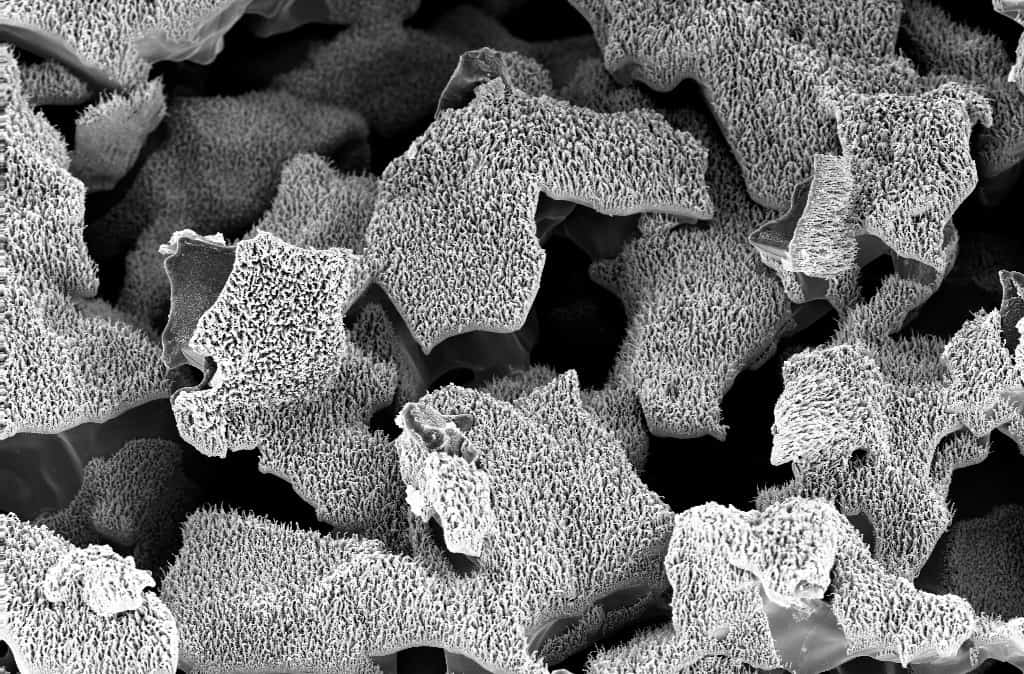

Technological scope: The low electrical resistivity and mechanical strength indicate why CNF are an attractive catalyst support material. The solution offered by Smoltek Hydrogen takes full advantage of the properties of CNF and the opportunities afforded by PECVD growth by growing vertical CNF on a PTL (above image). This method ensures contact between the CNF and the PTL while providing a high surface area substrate. Catalyst can then be deposited on top of this substrate. The vertical orientation of the CNF facilitates coating of the surface with additional layers of material, such as corrosion protection layers or catalyst particles.

Your data will be handled in compliance with our privacy policy.

News

January 28, 2026

Smoltek Hydrogen, has been selected as one of nine Swedish cleantech companies to join the Swedish-German Cleantech Platform 2026. This strategic program, managed by the Swedish Energy Agency and the German-Swedish Chamber of Commerce, gives the opportunity to accelerate the company’s commercial expansion into Germany — Europe's leading and most dynamic market for green hydrogen and fuel cell technology.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 4, 2025

Smoltek Hydrogen has received an order for samples of low iridium-load Porous Transport Electrodes (PTE) for PEM electrolyzers. The electrodes will be used in a joint development project with Heraeus Precious Metals, a global leader in precious metals.

News

October 30, 2025

Smoltek Hydrogen recently participated in the Hydrogen Technology World Expo 2025 in Hamburg, Germany – the world’s largest industry event for innovation in hydrogen and electrolysis technology. Ellinor Ehrnberg, President of Smoltek Hydrogen, was invited to a panel discussion on the topic “Overcoming the Key Obstacles in Electrolyzer Expansion”

News

June 12, 2025

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.