Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Hydrogen is attending the 29th European Fuel Cell Forum 2025 (EFCF) in Lucerne, Switzerland. The technical exhibition will offer industry and research institutions the opportunity to showcase systems, new materials, innovative systems, system components, test benches, electrolysis technology, research results etc.

By showing that we can run a PEMWE with only 0.1 mg/cm2 of iridium, 2 A/cm2 proton current density for 250 hours of continuous operation – we are unlocking green hydrogen at the manufacturing scale of tens of gigawatts each year! This is the key to decarbonize steel and base chemicals for a prospering planet.

Fabian Wenger, Head of R&D

Smoltek Hydrogen has successfully reduced the loading of Ir-based catalyst to 0.1 mg iridium/cm2, without compromising the overall performance of the PEM electolyzer. The reduction of iridium is critical in order to enable global mass manufacturing targets for green hydrogen production using PEM electrolysis.

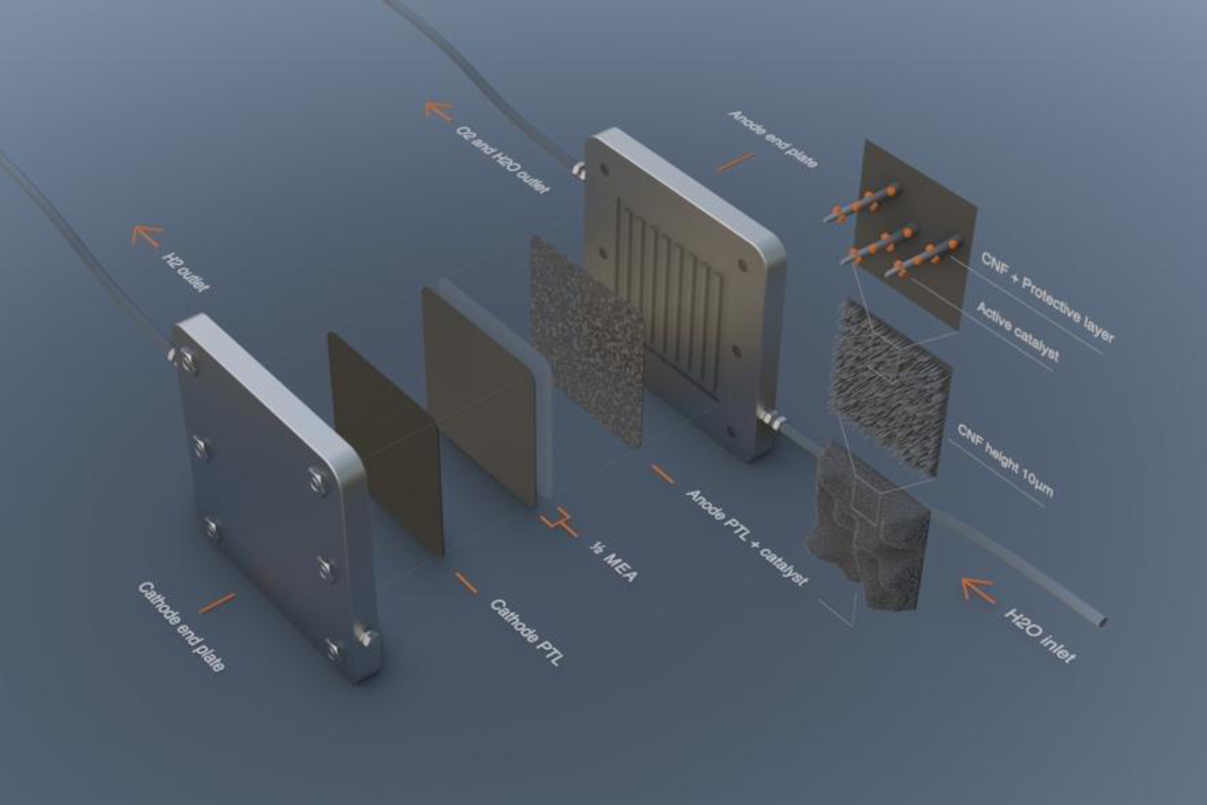

Smoltek Hydrogen’s unique Porous Transport Electrode (PTE):

Connect with:

Fabian Wenger on site.

- See you in Lucerne, July 1–4, 2025.

Smoltek Hydrogen PTE technical scope: The low electrical resistivity and high mechanical strength indicate why corrosion coated nanofibers are an attractive catalyst support material. The solution offered by Smoltek Hydrogen takes full advantage of the exceptional nanofiber properties on a PTL. This method ensures full contact between the nanofibers and the PTL while providing a high surface area substrate and catalysts can then be deposited on top of this substrate. The vertical orientation of the nanofibers facilitates coating of the surface with additional layers of material, such as corrosion protection layers or catalyst particles.

Your data will be handled in compliance with our privacy policy.