Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Research paper published in the proceedings of 2018 IEEE 13th Nanotechnology Materials and Devices Conference (NMDC), 2018, pp. 1–4.

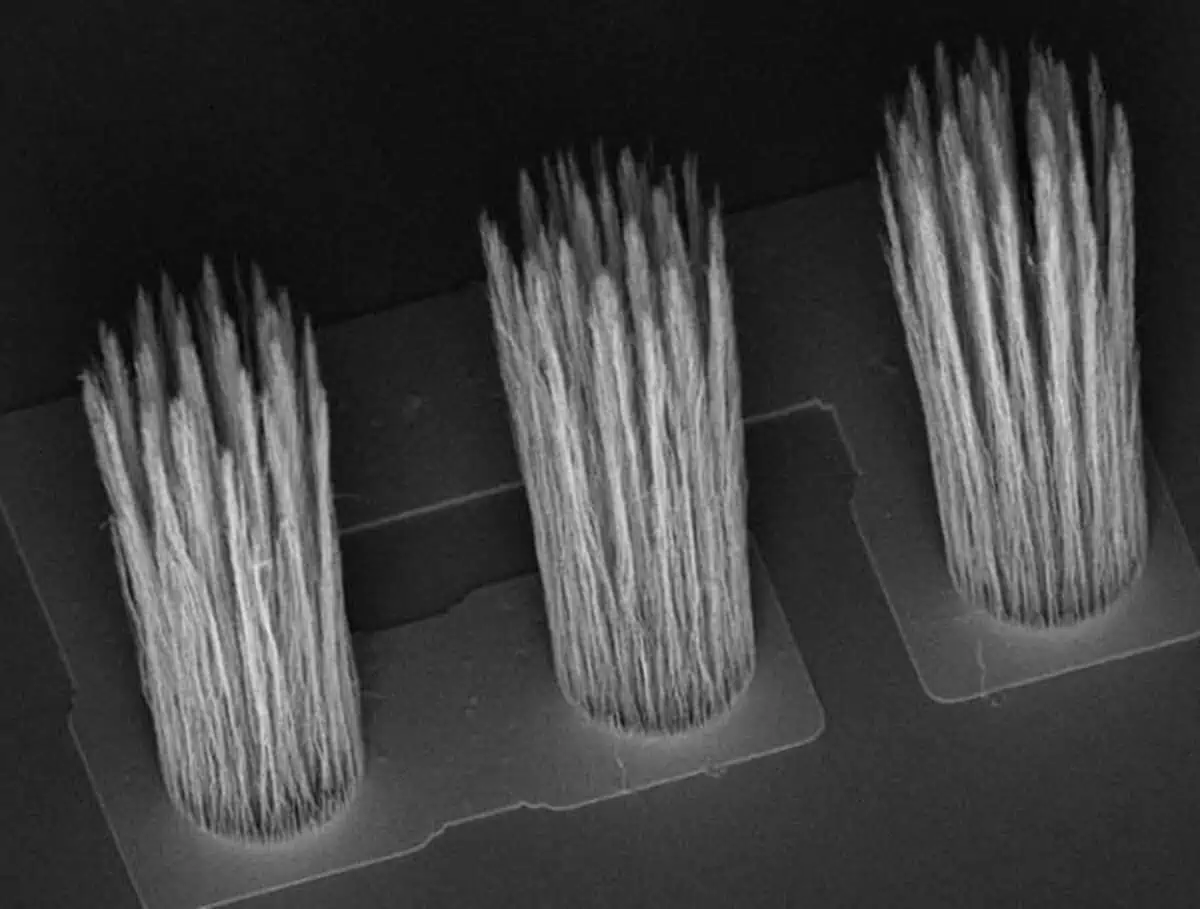

Vertically aligned carbon nanofibers (VACNFs) turf are characterized electrically and mechanically for prospective on-chip applications. The CNFs turf of 10 micrometer diameter and 20 micrometer pitch are fabricated at high temperature (550 °C) and CMOS compatible temperatures (390 °C) directly on silicon substrates where the number of CNFs per μm2 area are 13 and 38 for the respective growth temperature. The electrical characterization are accomplished by using kelvin test structures, and a polyethylene nephthalate based transparent probe card containing Titanium and Gold based probe bumps of size 10 micrometer in diameter and 20 micrometer pitch. The entire probing system not only have measurement precision but also minimizes the risks of damage to turf. The transmission line measurements (TLM)-based model approach is used for the electrical characterization to de-embed the contact resistance contribution and extract the intrinsic properties of a single CNF. Applying the model to the TLM measurements yields a conductivity of 6530 S/m and 67000 S/m for a single CNF grown at 390 °C and 550 °C, respectively. The hardness and reduced modulus of fine pitch turf are measured by using nanoindentation technique. The CNFs grown at 390 °C have higher elastic modulus (0.84–1 MPa) than 550 °C grown CNFs (0.26–0.84 MPa) due to dense growth.

Your data will be handled in compliance with our privacy policy.

Oops! Someone forgot to publish content. We apologize for the inconvenience.