Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Hydrogen is inviting you to become a developing partner for next generation of PEM electrolyzers.

The interest in green hydrogen is taking off, but the current need for large amounts of expensive iridium as catalyst material in PEM electrolyzers drives costs, making global scale-up difficult. With our technology for compact electrolyzers using a minimum of scarce catalyst particles, the green hydrogen industry can turn prospects into business.

The drop in demand for fossil fuels has made renewable energy sources more competitive, creating a favorable environment for the growth of the electrolyzer market.

The use of green hydrogen is expected to grow by a factor of 100 by 2030. The global electrolyzer market is forecasted to grow from USD 0.4 billion today to USD 3.5 billion in 2026 and reach USD 65 billion in 2030. A boom in terms of growth! However, a limiting factor is the availability and cost of expensive catalyst materials. This is where the new solutions from Smoltek are to play a vital role by radically reducing the amount of catalyst material needed in manufacturing electrolyzers and fuel cells.

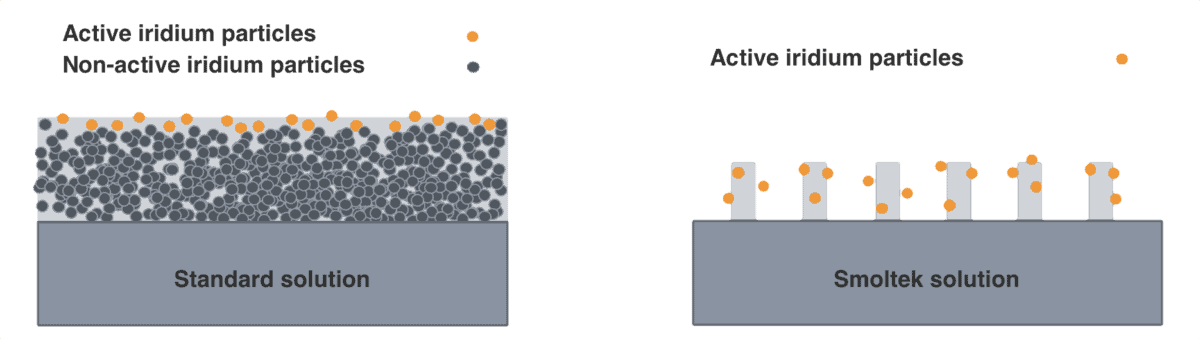

Smoltek’s advanced carbon nanofiber technology has a unique potential to enable more cost-efficient production of fossil-free hydrogen. PEM electrolyzers, specifically designed for intermittent energy supply, use a large amount of very rare and expensive catalyst particles (iridium) that today are used inefficiently – whereas Smoltek’s anode-side cell material technology makes maximum use of the catalyst particles. The result is 2–3 lower investment costs for electrolyzers in hydrogen plants thanks to decreased electrolyzer size.

Our main objective is to develop robust solutions for industrially relevant catalyst coatings in the energy conversion sector for the future. We build on our experience to scale up nanostructures developed for the semiconductor industry to also incorporate thin films that can catalyze effectively the reactions needed in gas diffusion electrodes for water electrolysis. The goal is to offer our customers superior properties in terms of stability and activity.

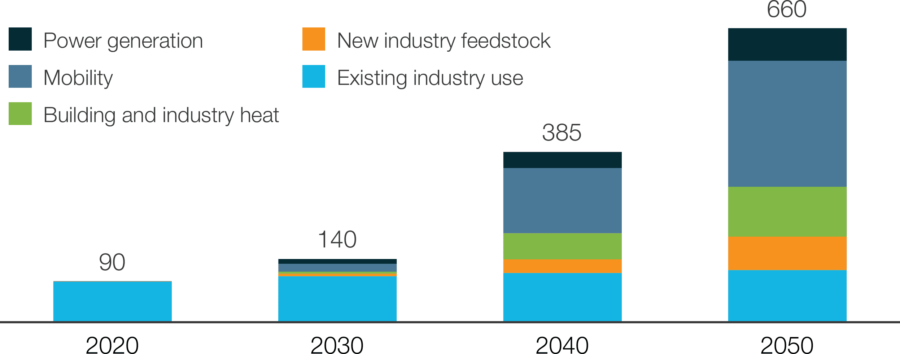

A huge green H2 (hydrogen) market is developing in the coming years. Five sectors will consume massive amounts of green hydrogen:

With new technology, we intend to grow a substantial business in the hydrogen ecosystem

Reduce the need for expensive iridium and platinum:

Green hydrogen is produced by electrolysis. Simply put, that is running electricity through water and gathering the released hydrogen. The apparatus in which this is done is called an electrolyzer.

Today, there are mainly two different electrolysis techniques for the production of hydrogen; Alkaline electrolysis (ALK) and Proton Exchange Membrane (PEM) electrolysis. ALK has been around the longest but the technology faces difficulties as it cannot be quickly adapted to varying input from green electricity, such as wind and solar. PEM on the other hand is more flexible and can handle the variations from the intermittent power sources.

The PEM technology’s benefits also include high efficiency, minimal upkeep requirements, and rapid startup times. It can also lower costs thanks to being able to produce more hydrogen when electricity is cheaper. These are the main reason why PEM electrolyzers are anticipated to expand at the highest rate when the industry will scale up hydrogen production.

The critical component of a PEM electrolyzer is the cell. It is the unit where the electricity in contact with water becomes hydrogen and oxygen. Each hydrogen production unit has vast numbers of these. Thus, the rapid growth of the production capacity of green hydrogen implies that the demand for electrolyzer cells will skyrocket.

With clever use of carbon nanofibers, we can reduce the use of rare and expensive noble metals by 50–70 percent while doubling or tripling the active surface area of the proton-exchange membrane (PEM) in electrolyzers and fuel cells.

And this will enable the green hydrogen revolution!

Electric heavy-duty vehicles are the key to fossil-free transport. When batteries would not provide a long enough range, fuel cells are the alternative. The vehicle is loaded with hydrogen, which the fuel cell transfers into electricity. This will be used for heavy-duty trucks, coaches, long-range passenger vehicles, and trains.

For long distances, heavy marine transports synthetic fuel is a convenient way to make the transports green. Existing combustion engines are run on synthetic fuels produced from green H2. Also, biofuels, lithium-ion batteries, and fuel cells will be used to make the sector fossil-free. Still, synthetic fuels are considered most attractive, given that the cost of producing hydrogen can be reduced.

Ammonia is the second most commonly produced chemical in the world, and it is derived from hydrogen. More than 80 percent is used as feedstock for fertilizer. The rest are used in making paint, plastic, textiles, explosives, and other chemicals. Ammonia production in 2018 generated around 500 million tons of carbon dioxide, where a large part comes from hydrogen produced by steam methane reforming. Making this from green hydrogen instead implies an immense growth of the electrolyzer market.

New steel works are being built all around Europe, something that has not happened for hundreds of years. The new steelworks will be using green hydrogen instead of fossil gas. Each ton of steel produced today is estimated to emit 2.2 tons of carbon dioxide—equating to about 11 percent of global carbon dioxide emissions. In Sweden, two well-known examples are the HYBRIT project run by SSAB, LKAB, and Vattenfall, and H2 Green Steel, a new ambitious company building new steelworks in Sweden and Iberia. Similar projects are seen, for instance, in Germany. For each new steelworks, a new large-scale hydrogen plant is being built.

Green hydrogen can be used for high-grade industrial heating in, for example, the cement industry, which accounts for 8 percent of global carbon dioxide emissions. Emissions can be reduced by a third by using green hydrogen to heat the cement kilns. (The remaining two-thirds come from the chemical reaction that produces cement and must be captured and stored or reduced by other means.)

Green hydrogen means that electricity from renewable sources is used, like wind, water, and solar energy. The wind and solar power capacity are planned to be built up at a large scale globally to match the demand. The large volume production combined with the technology running down the experience curve indicates an attractive cost per kilowatt from green electricity. For example, wind power is increasingly being produced in large offshore wind farms in the coming decade. Wind power already reaches a lower cost per kilowatt than new nuclear power.

According to the report Hydrogen for Net-Zero by Hydrogen Council and McKinsey & Company (2021), green and low-carbon hydrogen can be used to avoid 80 billion tons (80 GT) of cumulative carbon emissions from now through 2050. With an annual abatement potential of seven billion tons (7 GT) in 2050, hydrogen can contribute 20 percent of the total reduction needed in 2050.

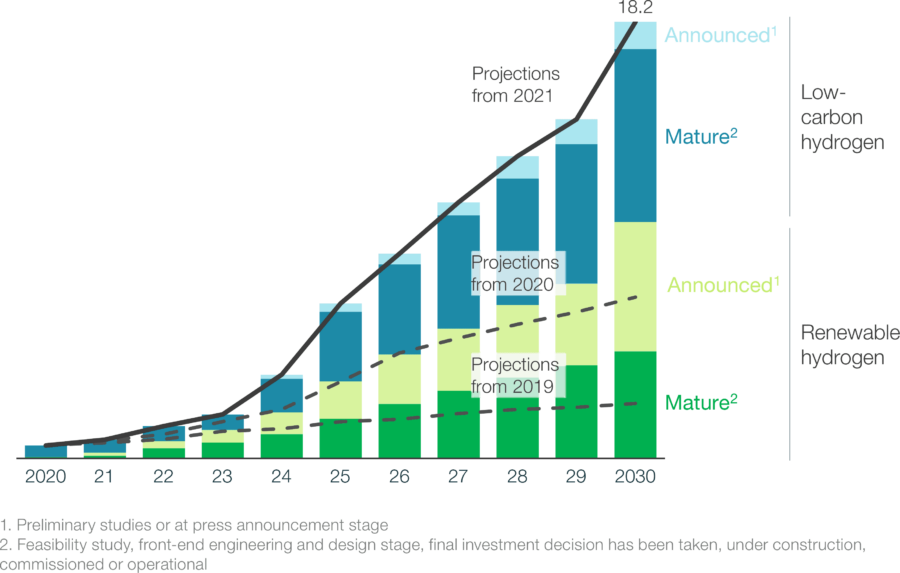

Production capacity needs to be expanded rapidly to meet the strong demand for hydrogen. And indeed, we see a rapid growth in announced or started projects to build hydrogen production facilities. In fact, the growth is so fast that the Hydrogen Council’s growth forecasts have had to be bumped up every year in recent years.

In the report, Hydrogen for Net-Zero, Hydrogen Council, and McKinsey & Company writes that players have announced more than 18 million tons of green and low-carbon hydrogen production through 2030. (See figure below.) Additional announcements include nearly 13 million tons of green and low-carbon hydrogen production capacity with deployment beyond 2030. The green and low-carbon hydrogen production volume announced in 2021 exceeds 30 million tons, more than 30 percent of the global hydrogen demand.

With our carbon nanofibers (CNFs) fabrication technology, we develop material solutions that enable more efficient solutions in the hydrogen industry.

Currently, we focus on improving the electrochemical cell in PEM electrolyzers and fuel cells. The cell enables the conversion of electricity into hydrogen and vice versa. Thus, it’s a key component in storing and transmitting renewable energy and decarbonizing industry, transportation, and heating.