Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Research paper published in the IPC APEX EXPO Conference Proceedings, March 23–27, 2014.

V Desmaris, S Shafiee, S Kabir, A M Saleem, A Johansson, P Marcoux • April 16, 2014

While the density of chip-to-chip and chip-to-package component interconnections increases and their size decreases the ease of manufacture and the interconnection reliability are being reduced. This paper will introduce the use of embedded fibers in the interconnections as a means of addressing these issues.

Flip chips bumps are evolving from large solder balls down to small thin copper pillars. Some copper pillars are solder capped and use a thermo-compression reflow attachment process. Smaller diameter copper pillars, while desirable by users, present a significant challenge to assemblers and reliability issues for end-users.

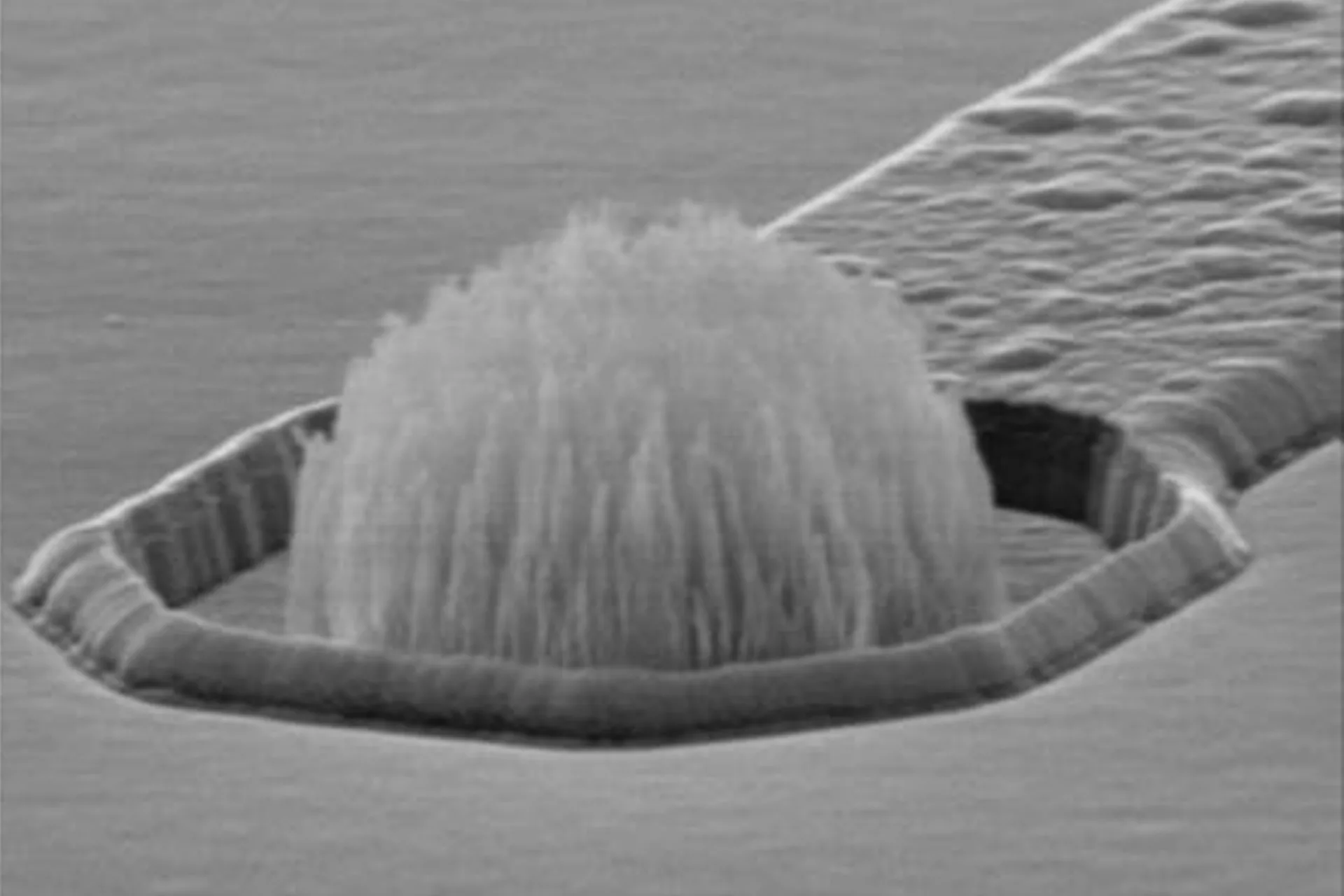

Nanostructures in the form of carbon nanotubes have been evaluated for years. The recently created a means of growing metallic carbon nanofibers, CNF’s, to micro bumps which are solderable. When embedded with solder the fiber bumps produce robust component interconnections which can be less than 10 um in diameter and up to 20 um high. Attachment of the fiber micro bumps uses conventional thermo-compression bonding.

Results from the most recent evaluations will be presented indicating electrical performance and showing ease of manufacture

Your data will be handled in compliance with our privacy policy.