Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Hydrogen develops electrodes for hydrogen fuel cells and electrolyzers for sustainable energy solutions to secure electricity supply. By reducing expensive catalyst materials and enhancing catalyst utilization we increase cost-performance for the scale-up of fossil-free hydrogen applications.

Smoltek Hydrogen’s new porous transport electrode (PTE) can reduce iridium loadings in PEM electrolyzers by up to ~95% compared to conventional technologies – enabling sustainable solutions for future generations.

Our offer

Smoltek Hydrogen’s catalyst coated substrate technology uses patented nanofiber deposition to create a porous transport electrode (PTE) with a 30x larger active surface area, ensuring nearly all of the catalyst material actively participates in the reaction. We partner with technology manufacturers throughout the PEM electrolyzer value chain to overcome the iridium bottleneck. Below are key collaboration opportunities for different industry segments.

Fuel cell systems require expensive PGM catalysts and face contact resistance challenges limiting performance. Smoltek CNF technology reduces PGM loading while lowering contact resistance, improving both economics and power output.

Complete PEM electrolyzer systems face iridium supply constraints limiting production scale-up. Smoltek PTE enables 20x more units from the same iridium supply while maintaining performance standards for industrial hydrogen production.

Membrane electrode assemblies traditionally rely on catalyst coated membrane (CCM) approaches requiring 2 mg/cm² iridium. Our PTE technology integrates with existing MEA production to deliver equivalent performance at 0.1 mg/cm² loading.

Porous transport layer producers can integrate our nanofiber technology to deliver enhanced PTL products with 30x surface area, positioning themselves as suppliers of next-generation electrode substrates.

Bipolar plate producers can integrate Smoltek PTE with their plates to offer complete electrode-plate assemblies. This positions them as system suppliers rather than component vendors, capturing more value in the electrolyzer stack.

Platinum group metal suppliers face customers limited by iridium availability. Smoltek technology enables these customers to scale production while requiring 95% less iridium per unit, expanding total market opportunity.

About us

Our approach combines 20+ years of carbon nanotechnology research from Chalmers University of Technology, patent protection across major electrochemical markets, and a team where most R&D staff hold Ph.D.s in materials science, electrochemistry, and nanotechnology processes.

Smoltek was founded in December 2005, as a spin-off from research at Chalmers University of Technology with a focus on precisely controlling carbon nanostructure growth. Since then, Smoltek has developed this technology into practical manufacturing processes. Smoltek Hydrogen applies this proven technology platform to address the iridium scarcity challenge in PEM electrolysis.

Smoltek’s intellectual property portfolio includes over 120 patents (granted and pending) covering core carbon nanotechnology, component structures, and manufacturing processes. This protection spans major markets including the US, Europe, China, Japan, and Korea, with growing focus on electrochemical applications.

Most of our R&D team holds Ph.D.s in materials science, electrochemistry, or nanotechnology engineering. Our technical depth spans from fundamental carbon nanofiber growth mechanisms to integration in PEM electrolyzer manufacturing, ensuring both scientific rigor and industrial scalability.

Our process

We work with industrial partners through a structured development process that aligns with how large enterprises evaluate and integrate new technologies. Each stage builds on the previous one, with clear technical and commercial milestones.

We provide engineering samples of our PTE for your initial testing. Your technical team gets direct access to our R&D engineers to discuss performance data, manufacturing parameters, and potential applications. This stage typically involves lab-scale testing to validate basic functionality and compatibility.

Following positive initial results, we establish a formal collaboration agreement. This can take the form of a joint development project, feasibility study, or technical advisory agreement. We conduct detailed analysis of technical requirements, manufacturing integration, and commercial viability specific to your applications.

With proven technical and commercial feasibility, we forge a licensing partnership. You gain access to our IP portfolio, manufacturing know-how, and design documentation. Your engineering teams can then perform detailed design work and integrate our technology into your production processes.

Our relationship continues through commercial production. Your team retains access to our R&D specialists for technical support, process optimization, and co-development of next-generation solutions. This ensures continuous improvement and helps address evolving requirements.

Features

PEM electrolyzer manufacturing faces critical constraints from iridium scarcity and inefficient catalyst utilization in conventional CCM approaches. Our PTE technology solves these fundamental limitations through advanced nanofiber architecture and optimized catalyst deposition.

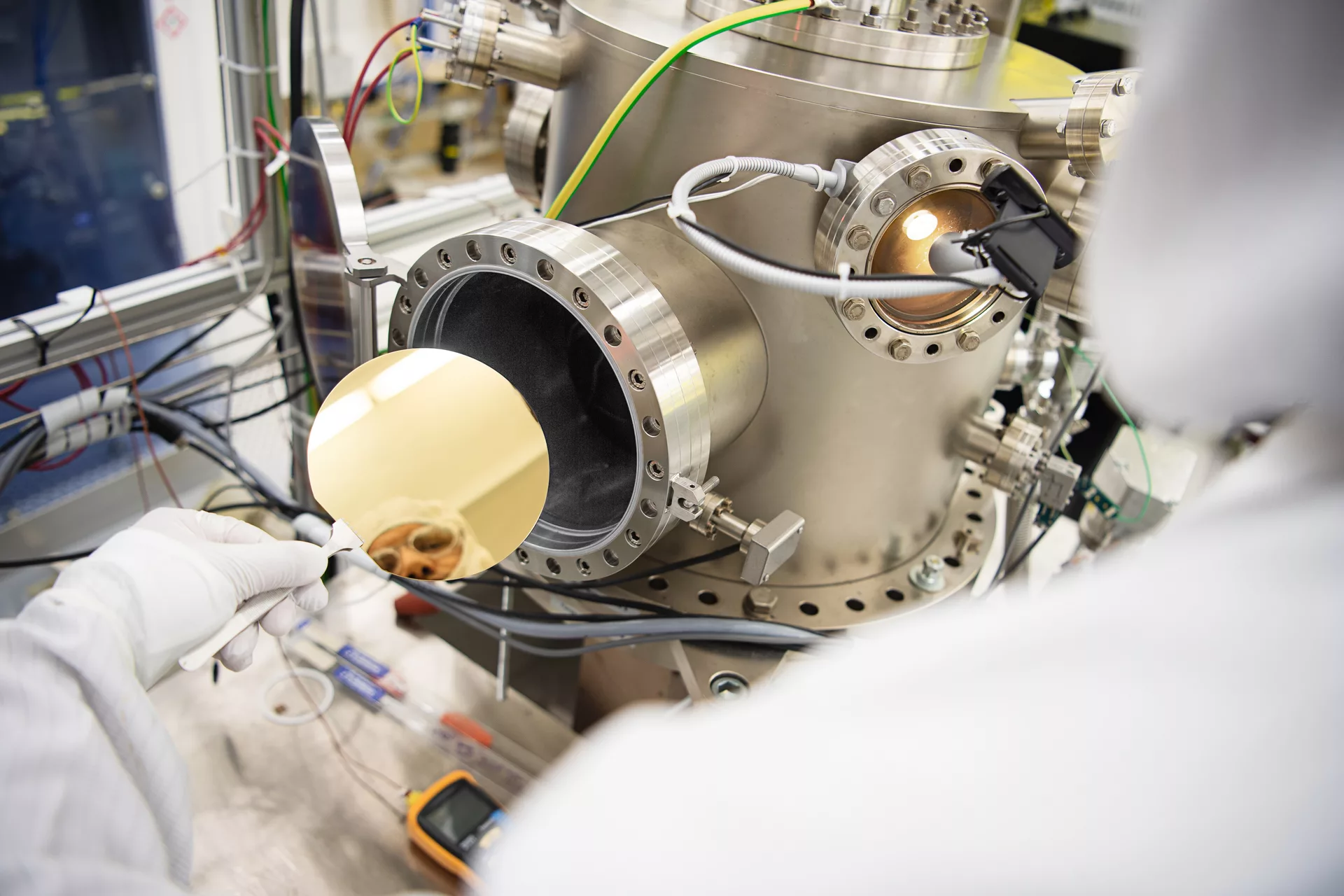

We grow vertically aligned carbon nanofibers on the PTL substrate, creating massive electrochemically active surface area within the same footprint. This 3D architecture enables precise control of fiber properties, multiplying reaction sites while maintaining optimal mass transport.

Our PTE ensures every iridium atom actively participates in the oxygen evolution reaction through direct electrical contact via the conductive nanofiber scaffold. This enables 0.1 mg/cm² loading versus 2 mg/cm² in CCM systems.

Each carbon nanofiber receives a thin platinum coating that prevents oxidation in the aggressive anodic environment. This protective barrier maintains structural integrity during long-term operation, ensuring reliable electrode performance throughout the electrolyzer’s operational lifetime.

Our catalyst-coated substrate approach works on most conductive substrates, not just titanium mesh. Unlike CCM, which limits manufacturing to membrane producers, our nanofiber technology allows more participants in the supply chain to offer enhanced electrodes for a variety of applications.

Frequently asked questions

We have demonstrated 0.1 mg/cm² iridium loading achieving 2.5 A/cm² at 2V while maintaining industry-standard performance. This represents a 95% reduction from conventional 2 mg/cm² CCM approaches. Our carbon nanofiber architecture creates 30x larger active surface area within the same footprint. Independent validation by Dr. Felix Büchi confirms equivalent performance with dramatically reduced precious metal usage.

We operate a fabless model with established manufacturing partnerships. SparkNano provides Spatial ALD technology while AGC Plasma Technology Solutions supplies PECVD systems for nanofiber growth. Our additive process uses standard industrial equipment and can be integrated into existing PTL production lines. We provide complete technology transfer packages including process specifications and quality control procedures.

Our licensing model includes three components: upfront licensing fees for patent access, non-recurring engineering fees for integration support and qualification assistance, and production royalties based on net sales of products incorporating our technology. The specific terms are structured based on your application and volume requirements.

We start with PTE components for PEM electrolyzers as our immediate market focus. The development roadmap includes fuel cell applications where our nanofiber technology reduces contact resistance, followed by other electrochemical systems requiring enhanced surface area and low precious metal loading. Each application builds on the same core carbon nanofiber platform.

Our R&D team works directly with your engineering teams throughout the integration process. This includes design optimization for your specific applications, process parameter adjustment, qualification testing support, and ongoing technical consultation. We maintain this relationship through production and future product development.

Evaluating new electrode technology requires understanding performance specifications, manufacturing requirements, and integration pathways. Here are answers to common questions about our Smoltek PTE technology from our technical discussions with industry partners.

We actively seek partnerships with electrolyzer manufacturers and component suppliers to bring PTE technology to market. Our R&D team works directly with prospective partners to evaluate commercial opportunities and address specific integration challenges.

Contact usOur Promise

We understand that adopting disruptive technology requires transparency and predictability. Our partnership approach focuses on working together through each technical and commercial milestone in a disciplined and structured way.

You don’t need to commit to a full-scale license right away. We recommend starting with specific projects, such as feasibility studies or joint development work, to address particular technical challenges. This approach enables your engineering teams to validate our technology within your existing electrolyzer systems and applications before making larger commitments.

We follow a structured development plan with specific performance targets for each milestone. We have achieved our breakthrough target of 0.1 mg/cm² iridium loading with industry-standard performance. Extensive 1,000-hour durability testing validates the long-term stability of our electrode technology. This represents the critical threshold for commercial viability, enabling 95% reduction in precious metal usage compared to conventional approaches. Our strategic collaboration with Heraeus focuses on combining our respective expertise to enhance PTE functionality and efficiency, targeting higher hydrogen output per kilowatt in next-generation electrodes for PEM electrolyzers.

We cover all aspects of PTE development, providing support throughout your evaluation and implementation process:

This complete capability means we can support your project from initial samples through commercial manufacturing.

Whitepaper

A deep dive into Smoltek’s electrolyzer technology – get your free copy from Smoltek. This is not a marketing brochure, but a 15-page technical whitepaper authored by our nanotechnology experts. Learn about how CVD-grown carbon nanofibers can revolutionize hydrogen production, improve catalyst efficiency in PEM electrolyzers, and enable more efficient renewable energy storage.

Download