Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

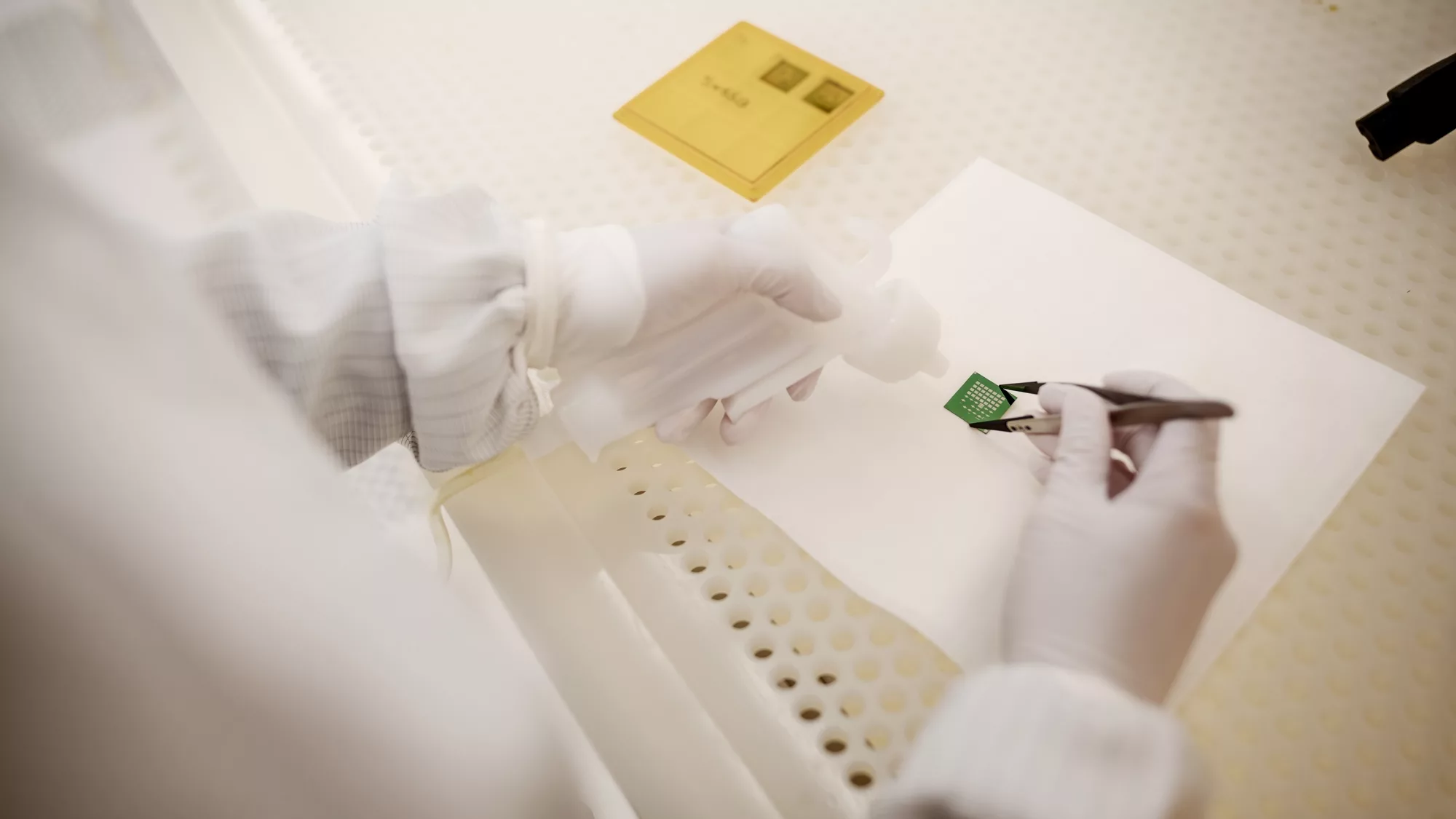

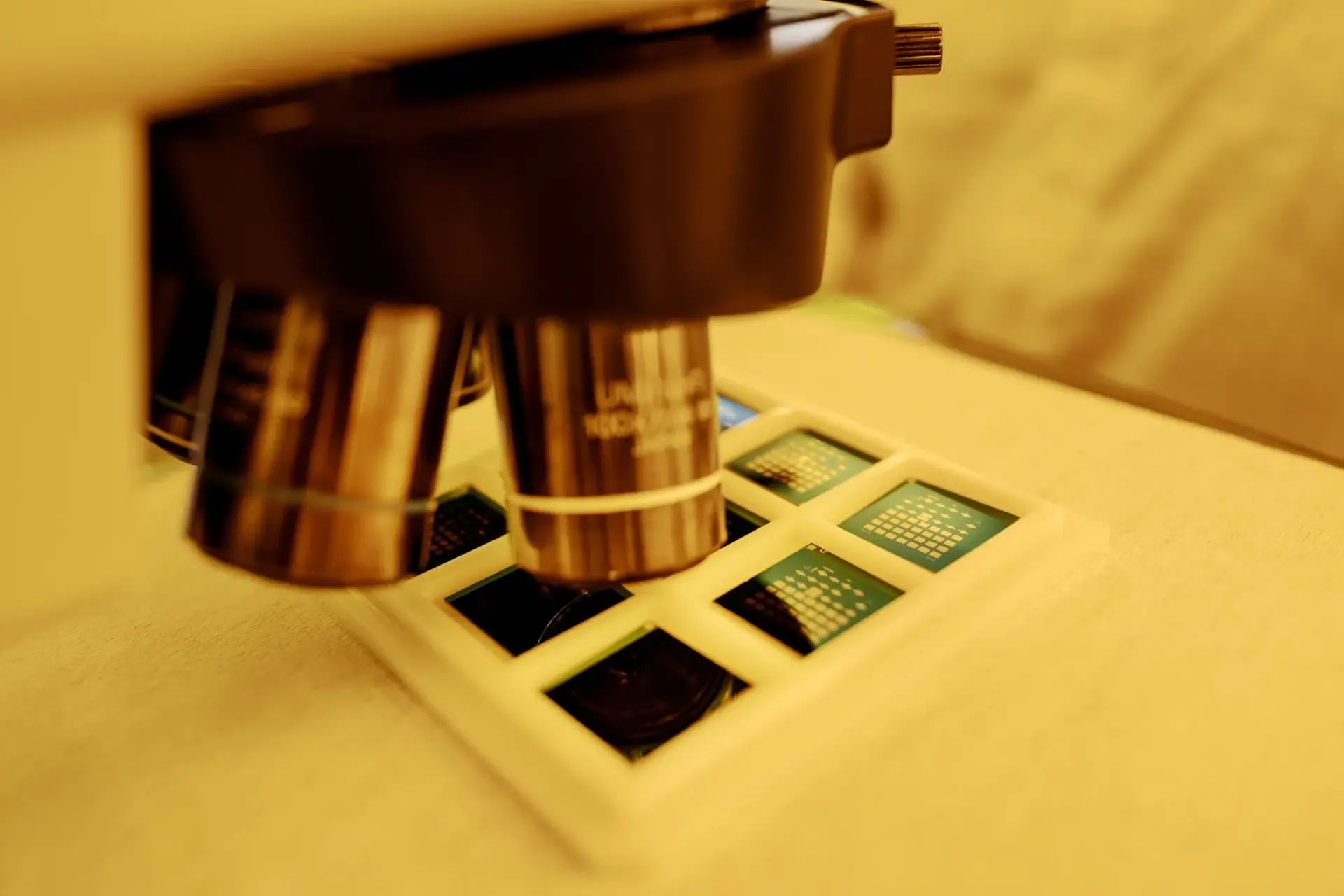

A main goal for Smoltek Semi is to develop an industrial process for mass production of discrete CNF-MIM capacitors at contract manufacturers (foundry), including a specially designed machine for large-scale production of carbon nanofibers.

“We have made great progress in 2021 in terms of the further development and industrialization of our CNF-MIM capacitors. Not least, I feel much more confident today when it comes to the status of the procurement of the industrial carbon fiber machine required to be able to begin mass production. Initially, we are focusing on developing a production process for discrete CNF-MIM capacitors used in mobile application processors, which is a niche that essentially all major players are interested in,” says Ola Tiverman, President of Smoltek Semi , which is responsible for licensing Smoltek’s technology to companies in the semiconductor industry.

Business opportunity for CNF-MIM capacitors

As the semiconductor industry has been able to continue to miniaturize the transistors in processor chips, the chips achieve increased performance, which gives us faster and increasingly powerful computers, tablets, mobile phones, etc. A consequence of this development is that the chip voltage must be lowered, and the frequency increased. This entails an increased need for so-called decoupling capacitors near the chip. In order to be placed close enough to the chip, these capacitors need to be extremely thin. Smoltek’s carbon nanofiber based capacitors (CNF-MIM) can solve these specific problems, especially for mobile phone chips (application processors). Target customers for Smoltek’s CNF-MIM capacitor technology are the largest capacitor manufacturers.

Procurement of a high-volume machine for growing carbon nanofibers

Specifying and procuring a machine for growing carbon nanofibers is required for mass production of Smoltek’s carbon nanofibers to the company’s CNF-MIM capacitors. This is an important part of Smoltek’s ongoing industrialization of the technology for discrete capacitors. The company’s goal is to be able to procure and install such a machine on site at a contract manufacturer (foundry) that will mass-produce the capacitors. This means that the entire process of manufacturing CNF-MIM capacitors is gathered under one roof, while Smoltek retains ownership of the production step that is unique to CNF-MIM capacitors. The company has received quotes from eight manufacturers of industrial machines for growing carbon nanofibers, and the procurement is now continuing with tests and negotiations.

Industrialization and creation of a supply chain

Smoltek has previously worked with the concept phase for how mass production of the company’s discrete CNF-MIM capacitors should take place at contract manufacturers (foundry) in terms of variables such as price, performance and production yield. The industrialization process is now entering a design phase together with contract manufacturers to design the components which are to be manufactured. If successful, this design phase, which constitutes phase three of five before mass production can begin, will lead to an engineering phase where the process steps are optimized and approved for high-volume production. This will result in a complete manufacturing process that will be possible to use for several products and by several customers. The goal is to complete the manufacturing process around the specially manufactured carbon fiber machine at a contract manufacturer. The last step before mass production can begin is to approve the actual product or products which are to be manufactured by subjecting it/them to a number of well-defined tests.

Customer relationships with major manufacturers of capacitors/product solutions

The potential customer base of companies that may be interested in mass-producing discrete CNF-MIM capacitors at a contract manufacturer with access to Smoltek’s carbon nanofiber machine and manufacturing process consists of a small number of very large players. These include the licensee in Smoltek’s ongoing evaluation collaboration. The goal is to reach one or several customer agreements with the aim of utilizing the developed process for mass production of discrete CNF-MIM capacitors. The main track is to license Smoltek’s technology to one or more large manufacturers, but our development of an industrial process also opens up for a product-based business model. Smoltek could thus in the future sell a license, and as a complement deliver physical components to the capacitor manufacturer.

Further technical development of the CNF-MIM technology

In parallel with the industrialization of Smoltek’s CNF-MIM capacitors, the company continues its successful work to further improve the concept’s performance. For example, the company recently attracted great interest and received a mention for best presentation/paper at the international PCNS conference in Milan, which is an important European event for the capacitor industry.

In 2021, Smoltek has focused a lot on improving the properties of the CNF-MIM technology that are important in addition to the capacitance density, which can be said to be the capacitor’s horsepower, but in the future the goal is to put more effort into further improving this important parameter and to demonstrate how thin CNF-MIM capacitors Smoltek is able to manufacture.

“It felt incredibly inspiring to be present during the PCNS conference in Milan this September, and to be able to meet people in the semiconductor industry again. I am convinced that physical meetings are necessary in order to secure the significant agreements that we are ultimately aiming for. The opportunity to meet physically again is also an advantage when we are now substantially strengthening Smoltek Semi’s team with additional skill sets and experience from the semiconductor industry. Several recruitment processes are now underway during the autumn, and they will be followed by additional recruitments in 2022,”

Ola Tiverman, concludes.

Image: Ola Tiverman, President of Smoltek Semi

Your data will be handled in compliance with our privacy policy.

News

February 24, 2026

An independent, third-party reliability test of our CNF-MIM capacitor technology has confirmed the reliability results communicated on February 5, 2026. The independent validation, performed by a major capacitor manufacturer, also reduces technical risk in the commercialization process and strengthens Smoltek’s credibility in ongoing negotiations with industrial partners.

News

February 5, 2026

Smoltek’s CNF-MIM capacitors demonstrate excellent stability in a new 1,000-hour life test at 85°C under applied 2 volts. No degradations were observed, and the capacitors exhibited more than 1,000 times lower current leakage compared to the previous life test.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 17, 2025

Smoltek Semi is currently optimizing the company’s advanced PECVD system to ensure implementation of its most recent technological innovations in CNF synthesis, enabling compliance with stringent customer requirements, prior to installation at ITRI in Taiwan.

News

November 5, 2025

Smoltek Semi has reached an important technical milestone in the development of the company’s carbon fiber-based CNF-MIM technology. The capacitors have successfully passed a 1,000-hour high-temperature durability test, confirming the robustness of the technology for advanced applications.

News

October 24, 2025

Smoltek Semi has acquired a plasma-enhanced Atomic Layer Deposition (ALD) system to implement its advanced dielectric stack on carbon nanofibers. The system will significantly reduce the iteration time of coating processes while enabling innovation and IP generation in dielectric stack technology for carbon nanofiber electrodes.