Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

In order to enable the extensive electrification and to replace fossil raw materials in industry, large investments are being made globally in the production, distribution and use of completely fossil-free hydrogen, so-called green hydrogen. In Sweden, some attention is certainly directed towards the steel industry's investments, but the huge interest in hydrogen that we see in many other countries has not yet reached this point.

In Sweden, there is a lot of talk about the Swedish steel industry’s investments in green hydrogen, but not much about the fact that the same is also happening on a large scale in China, the USA and the rest of Europe, or that the steel industry is just one of all future areas of use for green hydrogen.

Electrification of heavy transport is one such area, where today’s diesel-powered ships, trucks and trains can run on synthetic fuels made from green hydrogen – and where newly manufactured vehicles have fuel cells and can be refueled directly with hydrogen. Another large area of industrial use is to replace today’s fossil hydrogen gas (produced from natural gas) with green hydrogen gas in the production of artificial fertiliser.

Today, large quantities of the oil we use are produced in desert areas. In order to switch to fossil-free energy, gigantic solar parks are now being built to produce green hydrogen which is then shipped around the world. Pipelines and tankers already exist, and examples of countries with high ambitions for this are the United Arab Emirates, China and the USA.

The development in Europe has been accelerated by the fact that the EU allocated large funds this spring to investments in green hydrogen, which to some extent can directly replace the natural gas that is currently in short supply. Other areas are that hydrogen plants linked to solar and wind power plants can store the excess production and have the opportunity to use it as regulating power on days when the sun does not penetrate the clouds and the wind turbines are dormant.

Superior performance – an attractive investment

To produce green hydrogen, electrolyzers are used, which split water into hydrogen and oxygen. In order for it to be possible to scale up the production of electrolyzers, the industry sees it as necessary to reduce the consumption of the extremely expensive noble metal iridium by 95% – otherwise the price will skyrocket to levels that make the technology unusable.

“No one has yet succeeded in this, but we at Smoltek expect to be able to solve this with a new cell material based on carbon nanofibers.”

Ellinor Ehrnberg, President of Smoltek Hydrogen

The Smoltek proprietary cell material (ECM) is intended for the anode side of the cell in PEM electrolyzers. The material’s unique three-dimensional structure allows the amount of very expensive iridium particles to be reduced by up to 95%. By packing the catalyst particles more tightly, a considerable reduction in the size of the electrolyzer is also made possible.

A smaller and thus cheaper electrolyzer reduces the cost of building a new hydrogen plant by up to half, and also means reduced operating and maintenance costs.

Giant market for green hydrogen and electrolyzers

Hydrogen as a fossil-free raw material creates a potentially huge market for electrolyzer manufacturers, and also for Smoltek.

All over the world, a huge amount is invested in this area, not least in Europe. Already today, large amounts of hydrogen are produced for several energy-intensive industrial sectors that need to switch to fossil-free energy.

So far, however, it is only just under 5 percent of all hydrogen that is fossil-free. This means that there is a great demand for new technology to obtain more cost-effective methods for the production of green hydrogen.

Your data will be handled in compliance with our privacy policy.

News

June 27, 2025

Smoltek Semi has cleared a significant milestone in the development of next-generation CNF-MIM capacitors. Samples from the latest prototype generation, fabricated with an advanced dielectric stack composed of zirconium oxide (ZrO₂) and aluminum oxide (Al₂O₃) have demonstrated exceptional stability under both temperature and voltage stress.

News

June 18, 2025

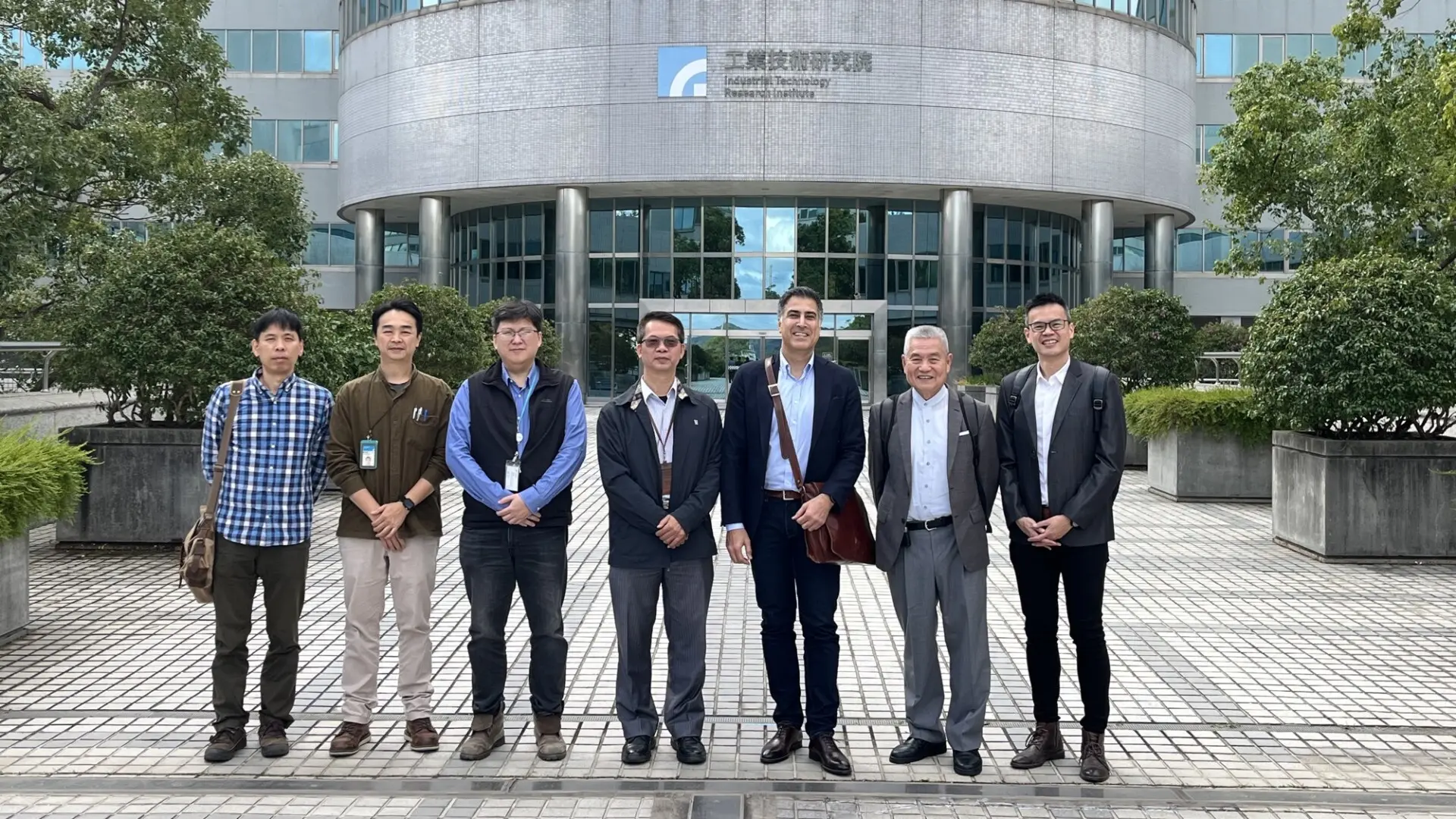

Smoltek Semi has initiated the signing of a technical service agreement with the Taiwanese Industrial Technology Research Institute (ITRI) that enables low-volume production of Smoltek's propriety CNF-MIM capacitors.

IR Blog Posts

June 16, 2025

Smoltek Semi joins an elite club of companies achieving 1 µF/mm² capacitance density, but stands alone in reaching this milestone with an ultra-thin profile. This breakthrough unlocks the under-chip real estate that represents the holy grail of capacitor placement in modern electronics.

News

June 12, 2025

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.

News

June 11, 2025

Smoltek Semi has successfully engineered an advanced dielectric stack that surpasses 1 microfarad per Square millimeter capacitance milestone.