Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek Hydrogen has placed an order for the design and engineering of a Prototype Coater for industrial growth of carbon nanostructures. The purpose is to verify that the nanostructures can be grown using the equipment from AGC Plasma Technology Solutions that has been selected for future mass production – a Plasma Enhanced Chemical Vapor Deposition (PECVD) tool that can be configured for substrates of several square meters.

PEM electrolyzers are equipment used to make hydrogen. They work with electricity and use iridium as catalyst to split water molecules into hydrogen and oxygen, and they will play an important role to reduce our carbon footprint, since the electrolyzers can make the production of e.g., steel, fertilizers, and fuels for heavy transport fossil free.

The PEM electrolyzer has several advantages over other electrolyzer types. The rapid start and stop times make it operate efficiently together with intermittent electricity sources (such as wind- and solar-power). This flexibility means that the PEM electrolyzer can produce cheap fossil-free hydrogen on windy and sunny days, when the electricity prices are low.

The hydrogen can then be stored and used when needed, for example in the industry, or be turned back into electricity again. This flexibility and cost advantage make it attractive to scale-up the production of PEM electrolyzers, even though they today use large amounts of the scarce metal iridium as catalyst.

Because iridium is such a limited resource, reducing its use in the electrolyzers is an absolute must, otherwise the scale-up of PEM electrolyzers will be too expensive. Already today the iridium price is around SEK 2 million and is expected to reach around SEK 8 million by 2030.

This requires new material engineering solutions for electrolyzer cells. Like the one Smoltek Hydrogen is in the midst of developing. It is a new cell material that substantially will reduce the amount of iridium in the electrolyzer cell.

The development of Smoltek Hydrogen’s electrolyzer cell material (ECM) is advancing according to plan, which is to lower the amount of iridium in the electrolyzer cell towards 0.1 mg/cm2. As of now the company has produced the same amount of hydrogen as a standard material (that uses 2.5 mg iridium/cm2) with only 0.5 mg iridium/cm2 and will most certainly reach the goal of the year, which is to have an even lower iridium loading.

First steps towards industrial manufacturing of the cell material

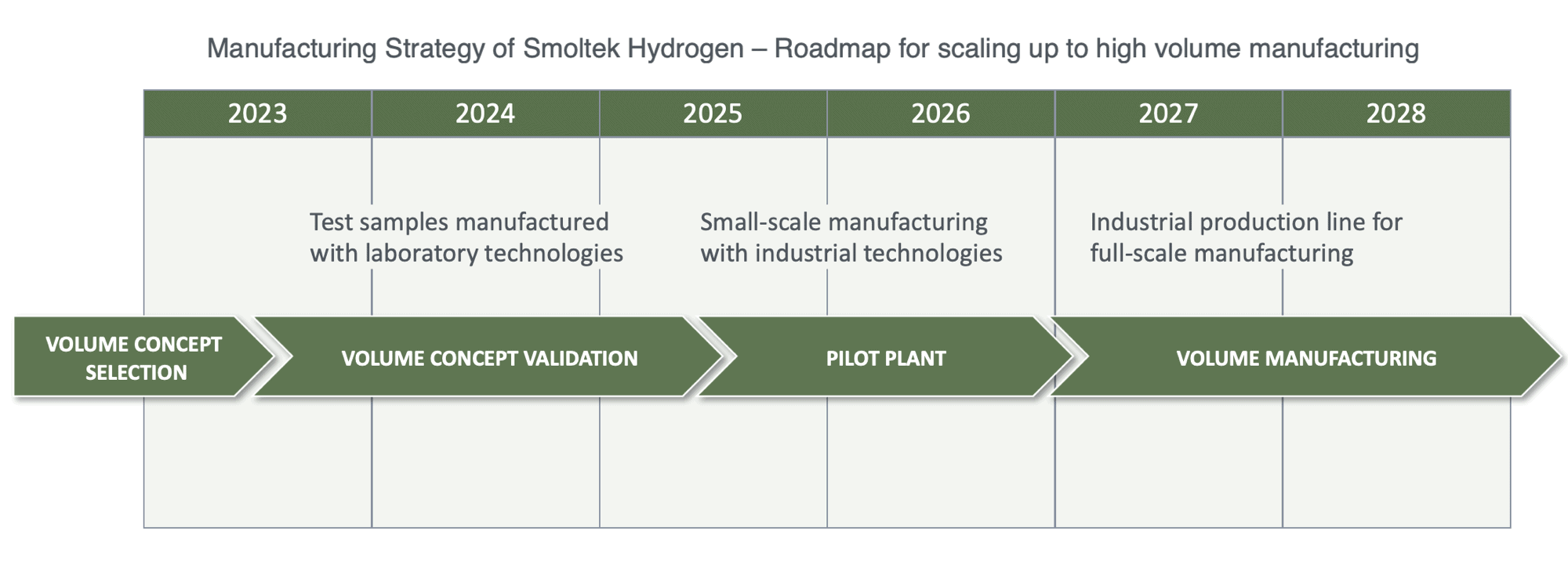

Besides the technology development, Smoltek Hydrogen is working in parallel with development of an industrial manufacturing concept for the cell material. Today the samples are produced with laboratory technologies, in low quantities and with typical area of only a few square centimeters, whereas the industrial manufacturing concept must be scalable to the high volumes foreseen, which is tens of thousands of square meters a year, and beyond.

As a first step towards industrial manufacturing, practical validation of the selected concept for the growth of nanostructures is needed, since it is a slightly different type of Chemical Vapor Deposition (CVD) process than used today. In order to do this Smoltek Hydrogen has placed an order with AGC Plasma Technology Solutions for the design and engineering of a new dedicated Prototype Coater tool. Smoltek has explored several different concepts and the selected PECVD technology is expected to work well for Smoltek’s growth process.

Smoltek and AGC Plasma Technology Solutions will together design a Prototype Coater tool that can mirror the output of full-size equipment. It will be placed in the Chalmers MC2 facilities in Gothenburg, where Smoltek currently has its nanostructure fabrication operations. This is an important first step towards industrialization of the Smoltek Hydrogen cell material.

The Prototype Coater will be used to validate that we have chosen the right concept for the future volume manufacturing, and also make it possible to develop industrial growth recipes before further scale-up. And even more important – it provides samples of industrial technology already now, when customers are to use our new material in the development of their next generation of PEM electrolyzers.

Shafiq Kabir, Head of Volume Processes at Smoltek Hydrogen

After successful validation of the Prototype Coater, Smoltek Hydrogen aims to order a Pilot Coater which is a smaller version of a final high-volume tool. This is a crucial component of AGC’s business model, since they guarantee the performance of the volume machine if their smaller coater is used to specify its requirements. The Pilot Coater will be used to produce test series for customers as well as for verification of the production technologies before volume manufacturing.

Smoltek Hydrogen plans to scale up the manufacturing in sync with customers’ product development processes, to ensure customers can obtain appropriate sizes and quantities of samples as well as final products when needed.

About AGC

AGC Plasma Technology Solutions is a new business unit within AGC Glass Europe SA, a European leader in flat glass. AGC Plasma Technology Solutions is providing low-pressure plasma coating technology and equipment. AGC Plasma is an expansive team of plasma coating experts specialized in innovative PVD and PECVD applications from R&D and new product development all the way through to equipment manufacturing and operational management of mass production coating plants. Visit the website www.agc-plasma.com to learn more about the equipment and services offered by AGC Plasma Technology Solutions.

People pictured in the top photo, from left: Amin Saleeem, Bastien Penninckx, Shafik Kabir, Erwan-Axel Morrisson (AGC), Fabian Wenger, Jeroen Schotsaert (AGC), Ellinor Ehrnberg, Réka Simon-Balint.

Your data will be handled in compliance with our privacy policy.

News

June 27, 2025

Smoltek Semi has cleared a significant milestone in the development of next-generation CNF-MIM capacitors. Samples from the latest prototype generation, fabricated with an advanced dielectric stack composed of zirconium oxide (ZrO₂) and aluminum oxide (Al₂O₃) have demonstrated exceptional stability under both temperature and voltage stress.

News

June 18, 2025

Smoltek Semi has initiated the signing of a technical service agreement with the Taiwanese Industrial Technology Research Institute (ITRI) that enables low-volume production of Smoltek's propriety CNF-MIM capacitors.

IR Blog Posts

June 16, 2025

Smoltek Semi joins an elite club of companies achieving 1 µF/mm² capacitance density, but stands alone in reaching this milestone with an ultra-thin profile. This breakthrough unlocks the under-chip real estate that represents the holy grail of capacitor placement in modern electronics.

News

June 12, 2025

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.

News

June 11, 2025

Smoltek Semi has successfully engineered an advanced dielectric stack that surpasses 1 microfarad per Square millimeter capacitance milestone.