Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

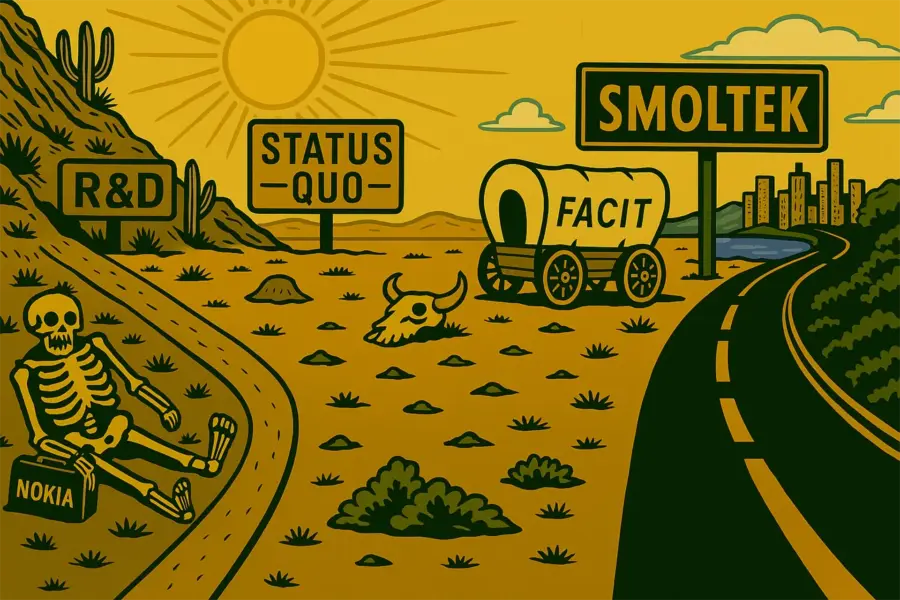

While traditional development processes often progress at a measured pace, truly disruptive technologies, such as Smoltek’s Porous Transport Electrode (PTE), can dramatically compress timelines. When faced with potentially market-changing innovations, industrial enterprises must choose between maintaining the status quo, slow internal development, or embracing partnership with innovative companies like Smoltek Hydrogen.

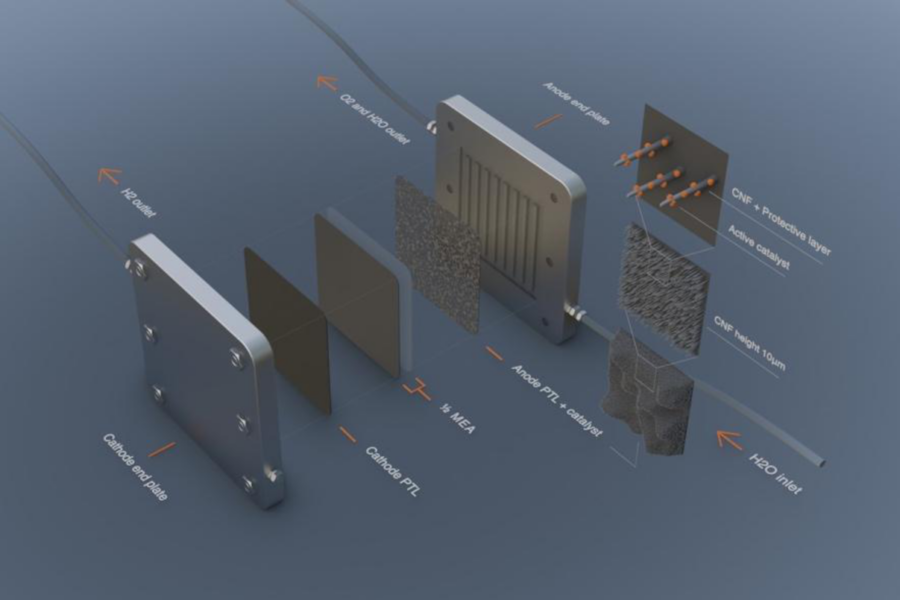

Smoltek Hydrogen has formed a strategic collaboration with Impact Coatings to assess the industrialization of Smoltek’s carbon nanofiber (CNF) technology for use in PEM electrolyzers and fuel cells.

Smoltek Hydrogen notice a strong interest from global industrial companies within PEM electrolyzers and fuel cells regarding our disruptive PTE-technology. Driven by the realization that early adoption provides crucial competitive advantages, there are now several hydrogen giants that are evaluating the technology.

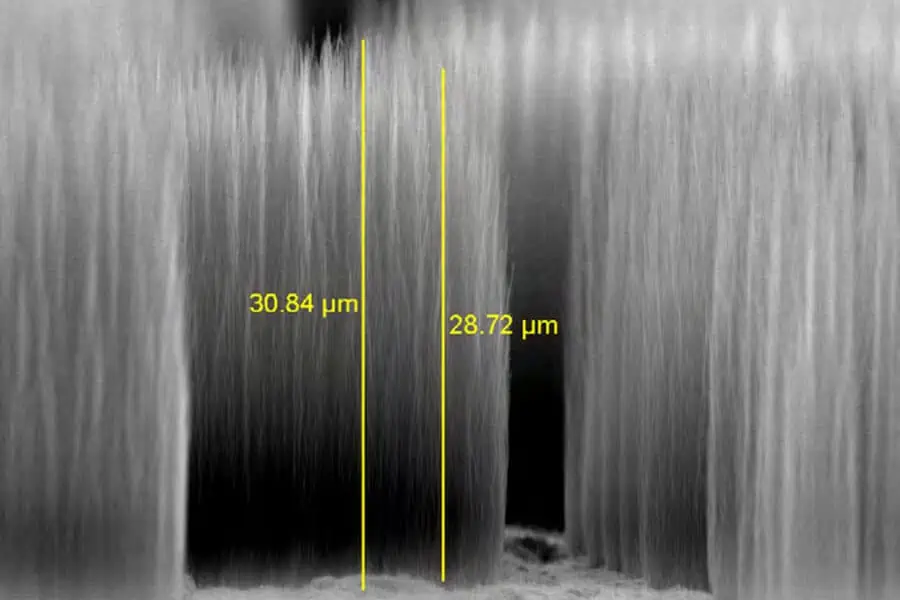

Smoltek's nanofibers dramatically increase catalytic activity for ultra-low-iridium electrolysis enabling more cost-effective green hydrogen production.

Smoltek Hydrogen has entered into a strategic collaboration with Heraeus Precious Metals to elevate the functional efficiency of porous transport electrodes in proton exchange membrane (PEM) electrolyzers to new heights.

Smoltek Hydrogen has produced hydrogen with only 0.1 mg of iridium per square centimeter in a 250-hour durability test – making our PTE a breakthrough technology for PEM electrolyzers.

In the race to make green hydrogen economically viable, researchers worldwide are pursuing the seemingly impossible: reducing iridium use in PEM electrolyzers by 95%. As Smoltek gets closer to this holy grail of 0.1 mg/cm², we examine how other technologies measure up.

Leading PEM technology expert Dr. Felix Büchi has completed an independent assessment of Smoltek Hydrogen’s Porous Transport Electrode (PTE) technology, confirming its unique ability to significantly reduce iridium usage while maintaining the same high performance in hydrogen production as conventional technology.

Leading PEM technology expert Dr. Felix Büchi has completed an independent assessment of Smoltek Hydrogen’s Porous Transport Electrode (PTE) technology, confirming its unique ability to dramatically reduce iridium usage while maintaining high performance in hydrogen production. In an exclusive interview with Smoltek Hydrogen’s President, Ellinor Ehrnberg, Büchi shares insights about the technology’s distinctive advantages and market potential.

Smoltek Hydrogen has been invited to participate in a Scandinavian delegation of technology leading hydrogen companies for a round-trip to Germany’s energy-producing regions in Rhur and central Germany.

A leading automotive manufacturer is interested in our technology for hydrogen solutions and has ordered number of prototypes of Smoltek Hydrogen's nanostructure coating modified for fuel cells.

Dr Felix N. Büchi, a leading specialist in PEM technology, has evaluated Smoltek Hydrogen’s ground-breaking technology for the Porous Transport Electrode (PTE) for PEM electrolyzers.