Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Latest news from Smoltek.

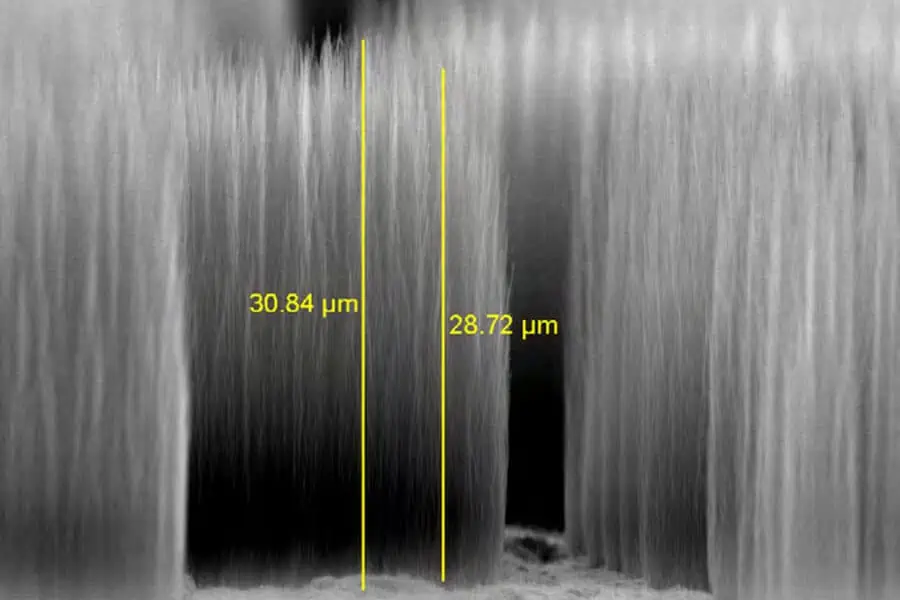

Smoltek Semi has cleared a significant milestone in the development of next-generation CNF-MIM capacitors. Samples from the latest prototype generation, fabricated with an advanced dielectric stack composed of zirconium oxide (ZrO₂) and aluminum oxide (Al₂O₃) have demonstrated exceptional stability under both temperature and voltage stress.

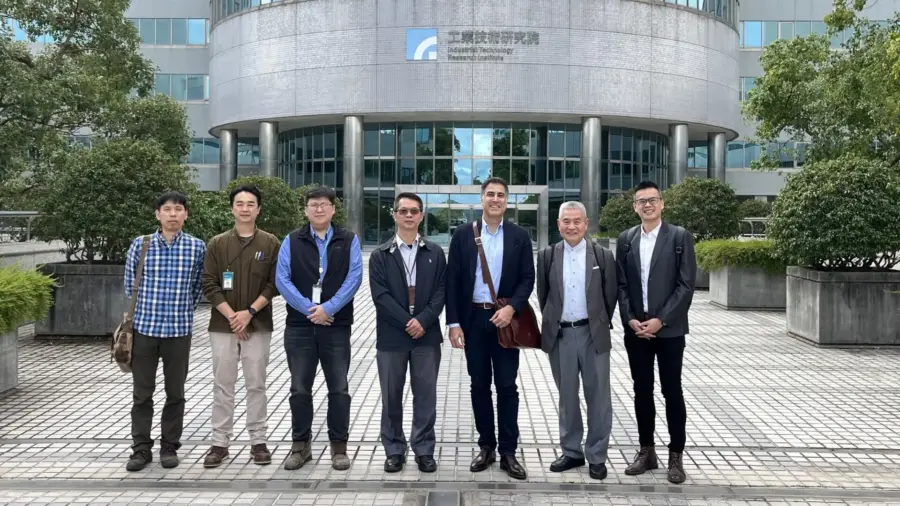

Smoltek Semi has initiated the signing of a technical service agreement with the Taiwanese Industrial Technology Research Institute (ITRI) that enables low-volume production of Smoltek's propriety CNF-MIM capacitors.

Smoltek Hydrogen, has on behalf of a leading global automotive manufacturer completed successful tests of its nanostructure fuel cell electrodes.

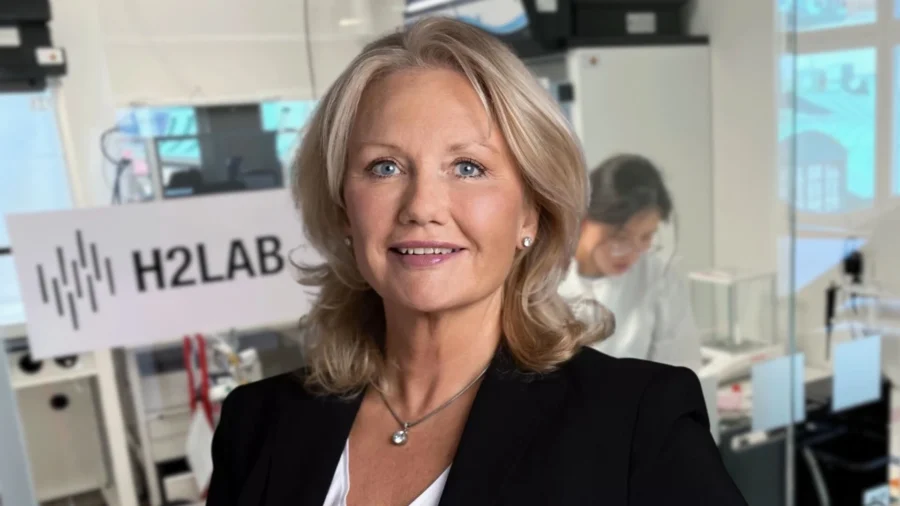

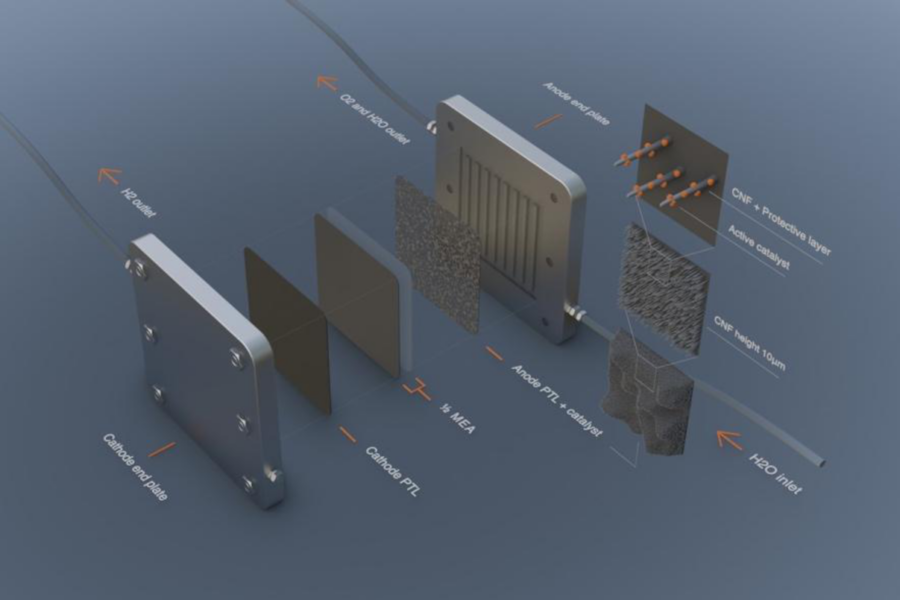

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.

Smoltek Semi has successfully engineered an advanced dielectric stack that surpasses 1 microfarad per Square millimeter capacitance milestone.

Smoltek Semi develops CNF-MIM – a proprietary capacitor technology based on carbon nanofibers, which is intended to meet the demands of next-generation electronics, including applications in AI, smartphones and automotive electronics.

Smoltek has been awarded a new patent within the hydrogen business area. The patent discloses a method for depositing conformally coated catalyst support for the PTL (porous transport layer) that provides both high catalytic activity and additional corrosion protection.

Smoltek held its Annual General Meeting on Wednesday, May 14, and the meeting resolved, in accordance with the nomination committee's proposal, to re-elect board members Gustav Brismark, Emma Rönnmark and David Gramnaes and to elect board members Oskar Säfström and Johan Rask. Oskar Säfström was subsequently elected Chairman of the Board.

Smoltek is awarded yet another patent in the Discrete CNF-MIM patent family. The innovation discloses a discrete capacitor component based on our CNF-MIM technology that can achieve unparalleled high capacitance density. This also brings our IP portfolio to comprise 95 granted patents.

Smoltek Hydrogen has formed a strategic collaboration with Impact Coatings to assess the industrialization of Smoltek’s carbon nanofiber (CNF) technology for use in PEM electrolyzers and fuel cells.

Smoltek Hydrogen notice a strong interest from global industrial companies within PEM electrolyzers and fuel cells regarding our disruptive PTE-technology. Driven by the realization that early adoption provides crucial competitive advantages, there are now several hydrogen giants that are evaluating the technology.

Smoltek's nanofibers dramatically increase catalytic activity for ultra-low-iridium electrolysis enabling more cost-effective green hydrogen production.