Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

One of the world's largest vehicle manufacturers is testing custom-made prototypes of a cell material that can significantly reduce the amount of iridium in an electrolyzer cell. The custom-made prototypes delivered by the subsidiary Smoltek Hydrogen have the potential to reduce the iridium load in electrolyzer cells by 95% compared to today's commercial materials, which is a prerequisite for large-scale production of fossil-free hydrogen.

Smoltek Hydrogen, a wholly-owned subsidiary of the Smoltek Group, has developed a cell material that can significantly reduce the amount of iridium in an electrolyzer cell, which has resonated around the world. Among other things, one of the world’s largest vehicle manufacturers has reached out to get the opportunity to test the cell material.

In the collaboration that the two companies have entered, the vehicle manufacturer is very interested in the unique construction, and in this initial project, Smoltek Hydrogen has delivered a specially manufactured and customized cell material for testing and evaluation.

We have manufactured prototypes where carbon nanofibers were first coated with platinum, and then applied iridium according to the customer’s requests. It has taken time to figure out exactly how to configure the prototypes, so that they can also be tested in their laboratory, but now they have just started testing the prototypes to see if they meet their requirements.

Ellinor Ehrnberg, President of Smoltek Hydrogen

If the test turns out well, we think this customer wants to start a larger project because they have big plans to use their fuel cell technology to also develop electrolyzers, and there seems to be no other solution to the iridium problem than the technology we have developed.

Ellinor Ehrnberg continues

The prototypes are based on Smoltek’s unique and patent-protected carbon nanotechnology, where the objective is to reduce the iridium load in the anode electrode in electrolyzer cells by 95% (which corresponds to 0.1 mg iridium/cm2), compared to today’s commercial materials (which use 2.0 mg iridium/cm2). Smoltek Hydrogen has already proven in long-term tests that the company’s cell material can produce the same amount of hydrogen at only 0.2 mg iridium/cm2, which makes it hopeful of reaching the final goal of 0.1 mg iridium/cm2.

The project with this customer has its background in the presentations of the technology that Smoltek Hydrogen carried out during the Electrochemical Society meeting in Gothenburg last fall, and next week we will present updated results at the 245th ECS meeting, which will be held in San Francisco.

Ellinor Ehrnberg concludes

Fact box: Smoltek Hydrogen’s cell material

Smoltek Hydrogen is developing a vertical nanofiber-based material for the anode porous transport layer (PTL) in PEM electrolyzer cells. The material consists of a sintered porous titanium layer with nanofibers, a conformal platinum corrosion protection and iridium catalyst (a thin nanoparticle layer of iridium). The material is one of the layers in an electrolyzer cell. When manufacturing electrolyzers, a large number of electrolyzer cells are assembled into a cell stack, which is the main element in the electrolyzer as it is where the electrolysis takes place and hydrogen is produced.

Your data will be handled in compliance with our privacy policy.

News

June 27, 2025

Smoltek Semi has cleared a significant milestone in the development of next-generation CNF-MIM capacitors. Samples from the latest prototype generation, fabricated with an advanced dielectric stack composed of zirconium oxide (ZrO₂) and aluminum oxide (Al₂O₃) have demonstrated exceptional stability under both temperature and voltage stress.

News

June 18, 2025

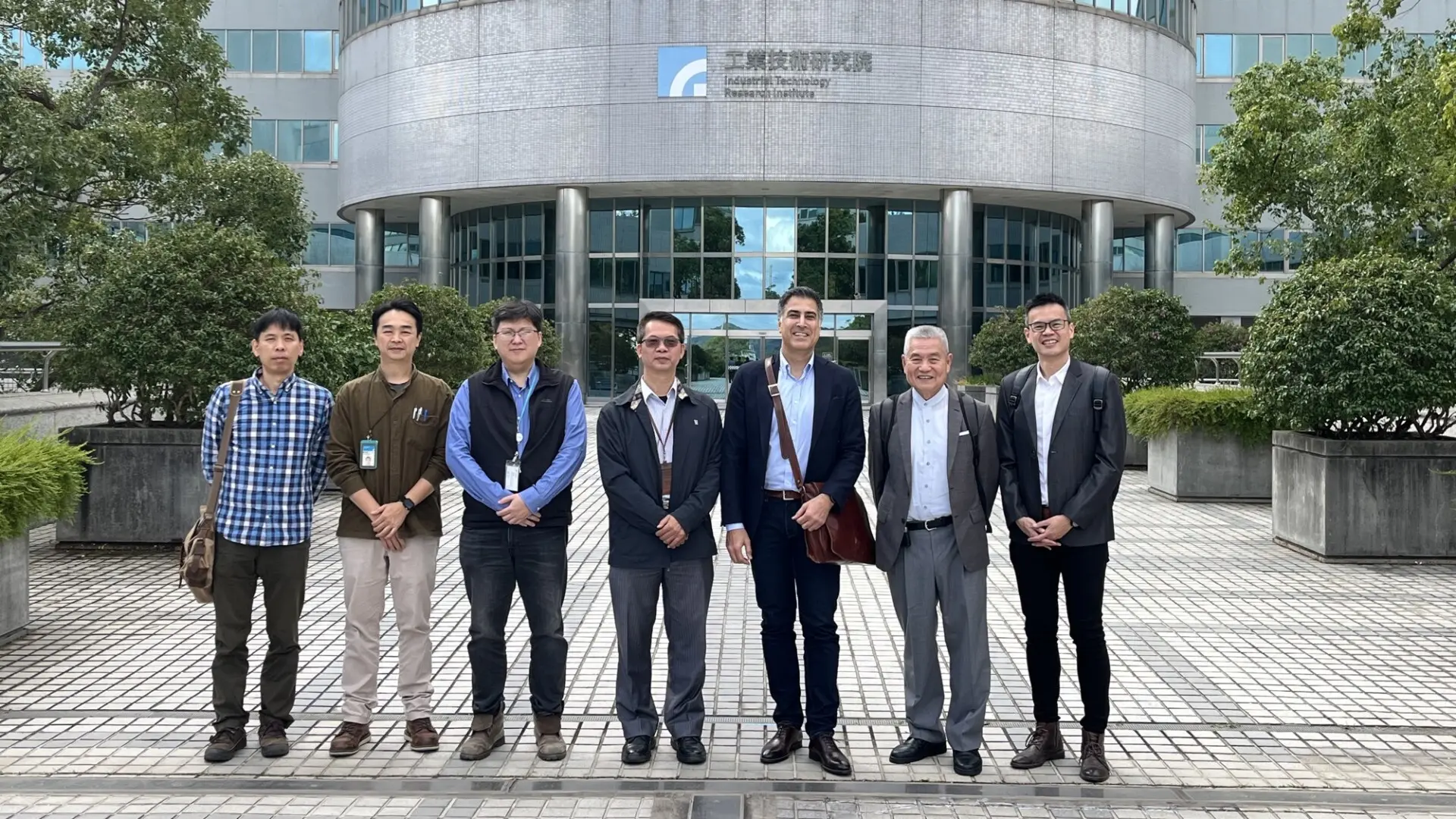

Smoltek Semi has initiated the signing of a technical service agreement with the Taiwanese Industrial Technology Research Institute (ITRI) that enables low-volume production of Smoltek's propriety CNF-MIM capacitors.

IR Blog Posts

June 16, 2025

Smoltek Semi joins an elite club of companies achieving 1 µF/mm² capacitance density, but stands alone in reaching this milestone with an ultra-thin profile. This breakthrough unlocks the under-chip real estate that represents the holy grail of capacitor placement in modern electronics.

News

June 12, 2025

Smoltek Hydrogen is developing Smoltek PTE – a proprietary porous transport electrode based on carbon nanostructures, which is intended to meet the requirements of next-generation PEM electrolyzers for the production of fossil-free hydrogen.

News

June 11, 2025

Smoltek Semi has successfully engineered an advanced dielectric stack that surpasses 1 microfarad per Square millimeter capacitance milestone.