Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Smoltek’s business division for the semiconductor industry, Smoltek Semi, focuses one hundred percent on capacitors. Why? After all, a capacitor is not a semiconductor. And what is the endgame for this venture? These are questions we address in this blog post.

A few weeks ago, we proudly announced that we had started production of capacitors in high-volume. But why the fuss about capacitors? After all, it is a severely price-pressured and already cheap commodity. And why is Smoltek’s division for the semiconductor industry, Smoltek Semi, doing this? A capacitor is not a semiconductor! And what’s the plan for the future? All this is the subject of this week’s blog post.

Yes, capacitors are a commodity. Yes, capacitors are cheap (they cost apiece just a fraction of a dollar). And yes, capacitors are under severe price pressure from the big boys.

So what on earth makes a small company up in the north, not yet profitable, bet on what must be one of the toughest markets in the world?

The answer is two-folded: The know-how to solve one of the electronic industry’s biggest problems in the continued development of increasingly powerful small devices. And the business opportunity that comes with that know-how.

Let’s unpack what this means, starting with the business opportunity.

Every device that contains chips also contains capacitors. Your smartwatch, smartphone, smart speaker; your tablet, laptop, and desktop computers; your tv, stereo system, and robot vacuum cleaner. Every electronic gadget you own. The same applies to larger systems like cars, medical devices, and industrial-process controllers.

In short, capacitors can be found everywhere. They are omnipresent. And there is a colossal demand for them. Every year, more than a whopping one trillion capacitors are produced worldwide.

Smoltek aims to grab a slice of that pie.

It sounds like the hubris of a startup when Smoltek claims to be able to cut even a slice of the pie. But it’s anything but hubris.

As you know, we have partnered with YAGEO, the world’s third-largest manufacturer of passive components like capacitors. With our know-how and YAGEO’s sales and distribution channels, we aim to jointly capture one-third of the capacitor market for the premium segment of mobile phones except iPhones.

Of course, Apple knows what we have to offer, but we don’t pursue them for now. They are working closely with a competitor, and we believe they will not jump ship any time soon.

We estimate that our addressable market buys between 3.5 and 4.5 billion capacitors each year. So even if the price apiece is only a fraction of a dollar, the overall sales impact is impressive.

It may seem strange that Smoltek focuses on an electronic component that is not a semiconductor. But there is a perfect reason for that. I have already hinted at what it is:

Capacitors are an absolute necessity for digital integrated circuits of semiconductors to work.To explain why, we need to go down the rabbit hole of the inner workings of integrated circuits and capacitors. If you don’t like the wonderland of electronics, skip this part and go straight to the last question: What’s the endgame?

Still here?

Good! Let’s follow the White Rabbit.

Although semiconductors can be used for more than just digital integrated circuits, digital integrated circuits, or chips for short, are what we’re talking about here. A chip consists of transistors that act as electrical switches. Each transistor represents a bit – a number that can be one or zero. A transistor turns on power to represent the value one and turns off power to represent the value zero.

Turning the power on and off can affect nearby devices. You may have experienced that the lights in your home blink when you turn on or off a kettle or other electrical appliance that draws a lot of power. This is because the rapid change in power demand creates a short-lived pulse, called a transient, which propagates from the appliance, through the wiring, to the lights. The same happens when transistors in a chip turn power on and off.

To make matters worse, transistors on a chip turn on or off simultaneously. They do so at the beat of a clock that ticks billions of times every second. Each transistor contributes a little to what adds up to a significant transient. This transient will propagate from the chip to other chips and components if not addressed. That can disrupt (and even destroy) the electronics, with devastating consequences.

Not only that. Transients rushing through the power-feeding tracks make them act as transmitting antennas that send out radio waves. Other tracks act as receiver antennas that pick up the radio waves and convert them into electricity. This way, the pulse is transmitted wirelessly from the supply tracks to other tracks. Tracks that may transmit ones and zeros that are at risk of flipping. Again, the consequences can be devastating.

To prevent these devastating consequences, mitigating outgoing and incoming transients is necessary. This is where capacitors come into play. When a capacitor is used for this purpose, it’s called a decoupling capacitor.

You can think of a decoupling capacitor as a shock absorber for the voltage supply to the chip. Quick voltage changes, both upward and downward, are smoothed out and become much smaller. They do this by absorbing and releasing energy as the supply voltage fluctuates.

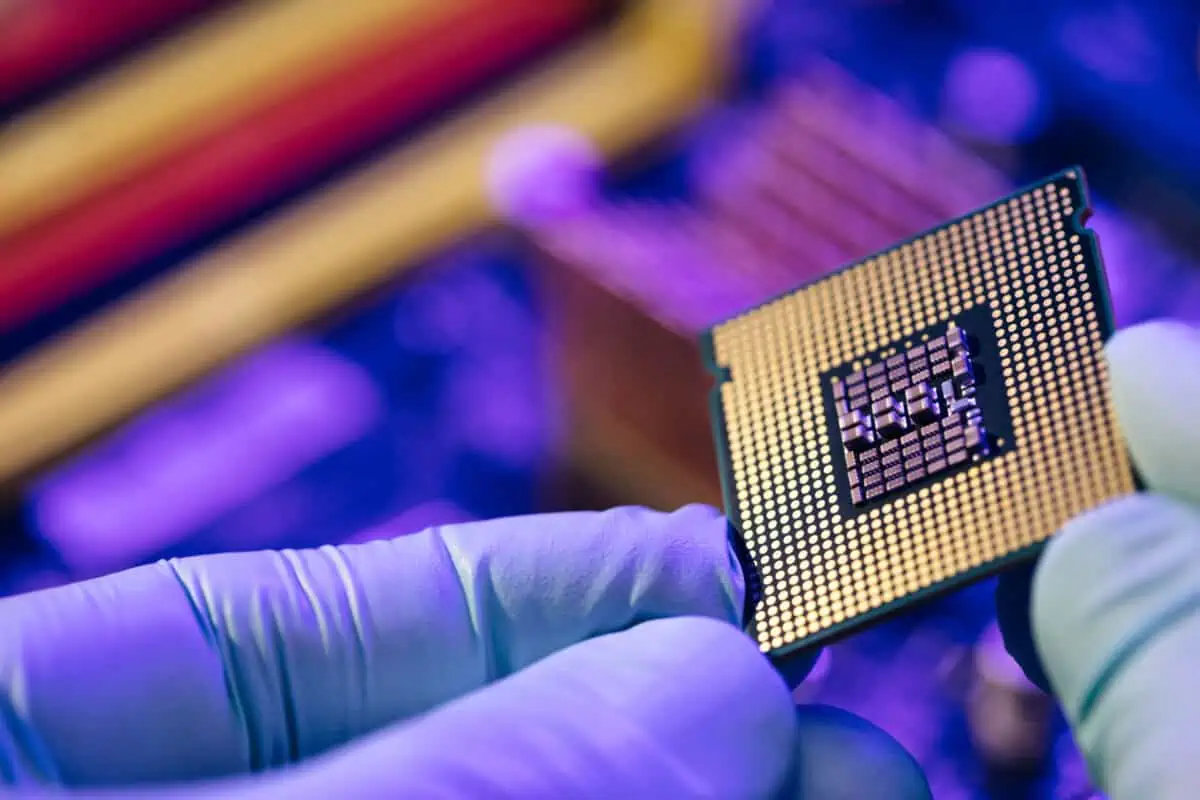

Some capacitors are lightning-fast at absorbing the energy but cannot absorb much. Others are slower but can absorb more. Therefore, several capacitors are often needed to protect a chip. A single smartphone processor today typically has eight decoupling capacitors.

That’s why capacitors are necessary for semiconductors and the semiconductor industry. However, the decoupling capacitors must be as close to the chip as possible for it to work.

In an ideal world, capacitors respond lightning-fast to power surges, but in reality, they don’t. The reason is spelled parasitic inductance.

Inductance refers to the property of an electrical conductor by which a quick change in current flowing through it induces (hence the name) a voltage that opposes this change, effectively slowing the rate at which current can change.

Unintentional and unwanted inductance is said to be parasitic. Parasitic inductance is everywhere, even in the wires between the capacitor and the chip. The longer the wires, the more inductance and the greater the resistance to sudden changes. That is the opposite of what we want to achieve.Thus, keeping the wires between a decoupling capacitor and its chip as short as possible is essential. Ideally, the capacitor should be inside the chip. But the next best thing for decoupling capacitors is to sit between solder balls under the chip. Such a capacitor is called a land-side capacitor (LSC).

It should be pretty obvious why landside capacitors must be small. They compete with the solder balls for space on the underside of the chip. The typical length and width of a capacitor vary between half and a few millimeters.

They must also be thin because the distance between the chip and the circuit board is smaller than the diameter of the solder balls. Commonly, for computer chips, the solder balls are only 0.5 or 0.4 millimeters in diameter.

In premium smartphones, the requirements are much tougher than that. They require ultra-thin capacitors. We are talking about tens of micrometers instead of millimeters.

When the thickness of a land-side capacitor gets down to 80 micrometers, 60 micrometers, or even 40 micrometers, many problems start to creep up.

The first challenge that manufacturers face is capacitance. This is the ability to save energy. It is necessary to create sufficient capacitance in the small area available without making the capacitor too high.

Another challenge for manufacturers is to create ultra-thin capacitors that are not so brittle that they cannot be handled industrially without breaking.

A third challenge is the strength of materials. One technique used today is to fill etched trenches in silicon substrates with an insulating material. However, there are limitations in how deep these trenches can be and how tightly they can be placed.

Fourth, last but not least, these challenges make the research and development of ever-thinner capacitors more complex and their production more expensive.

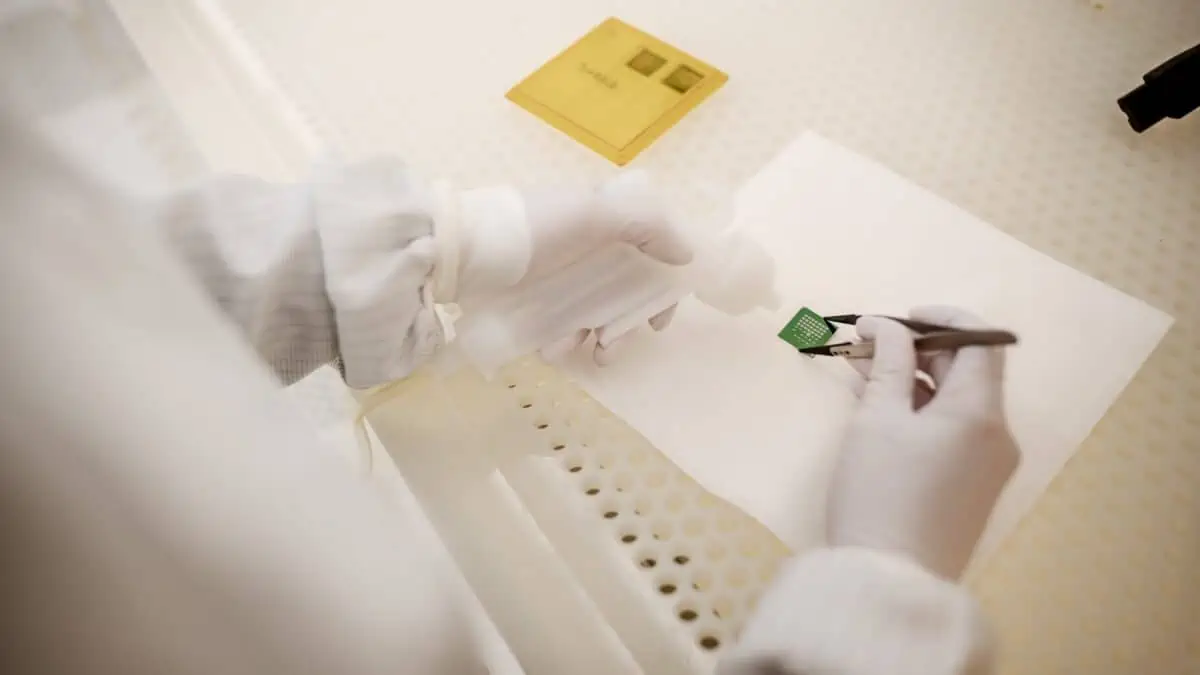

This is where Smoltek’s CNF-MIM capacitors enter the stage.

We expect CNF-MIM capacitors to have higher capacitance than a deep trench silicon capacitor (the closest competitor) of the same length, width, and height.

In addition, the CNF-MIM capacitor is expected to meet real-world requirements with flying colors: excellent capacitance stability, high breakdown voltage, low leakage current, and low series resistance and inductance.

To top it off, CNF-MIM capacitors aimed at high-end device segments are expected to be cheaper to produce, so we can compete on price and still have a good margin for capacitors.

Is the commercialization and mass production of CNF-MIM capacitors the endgame of Smoltek’s exploration in the semiconductor territory?

No.

CNF-MIM capacitors are just one of many applications in the semiconductor field for which carbon nanofibers can be used. If you’ve been around for a while, you might remember SmolTIM, SmolINCO, and SmolINPO. Our patent-protected solutions for heat dissipation inside chips, interposers with built-in decoupling capacitors and reinforced connection points for multiple dies, and solder balls with ultra-fine pitch (down to 5 micrometers).

However, we chose CNF-MIM capacitors because it was pretty obvious business-wise. There is an imminent need for ultra-thin capacitors, and the market is vast.

Our patents protect the other technologies, so we can safely focus on launching sales and rolling out mass production of CNF-MIM capacitors. Once it is up and running, we can return to the other technologies and consider which one to bring to the market next.

Another benefit of starting with producing CNF-MIM capacitors is that it offers unequivocal proof for foundries that our technology works in their environments.

Foundries are the factories that make the semiconductor itself. They are arguably the most expensive factories humans have ever built. Each costs several billion US dollars. Thus, their owners and investors don’t take any risks. They can’t afford it.

It is too risky for them to insert Smoltek’s carbon nanofiber growing technology into their CMOS chip manufacturing process without proof that it works.

Now they get that proof.

The same technology used by foundries makes the CNF-MIM capacitors. Of course, with the addition of our carbon nanofiber growth technology. And that’s the point. Our technology works with theirs without causing any problems.

Well, that’s pretty much all there is to know about why we chose capacitors as the first commercialized application of carbon nanofibers.

What do you think of the blog post? Was it too long? Too technical? Or maybe just right? Something you have missed? Head over to LinkedIn and leave a comment.

Your data will be handled in compliance with our privacy policy.