Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

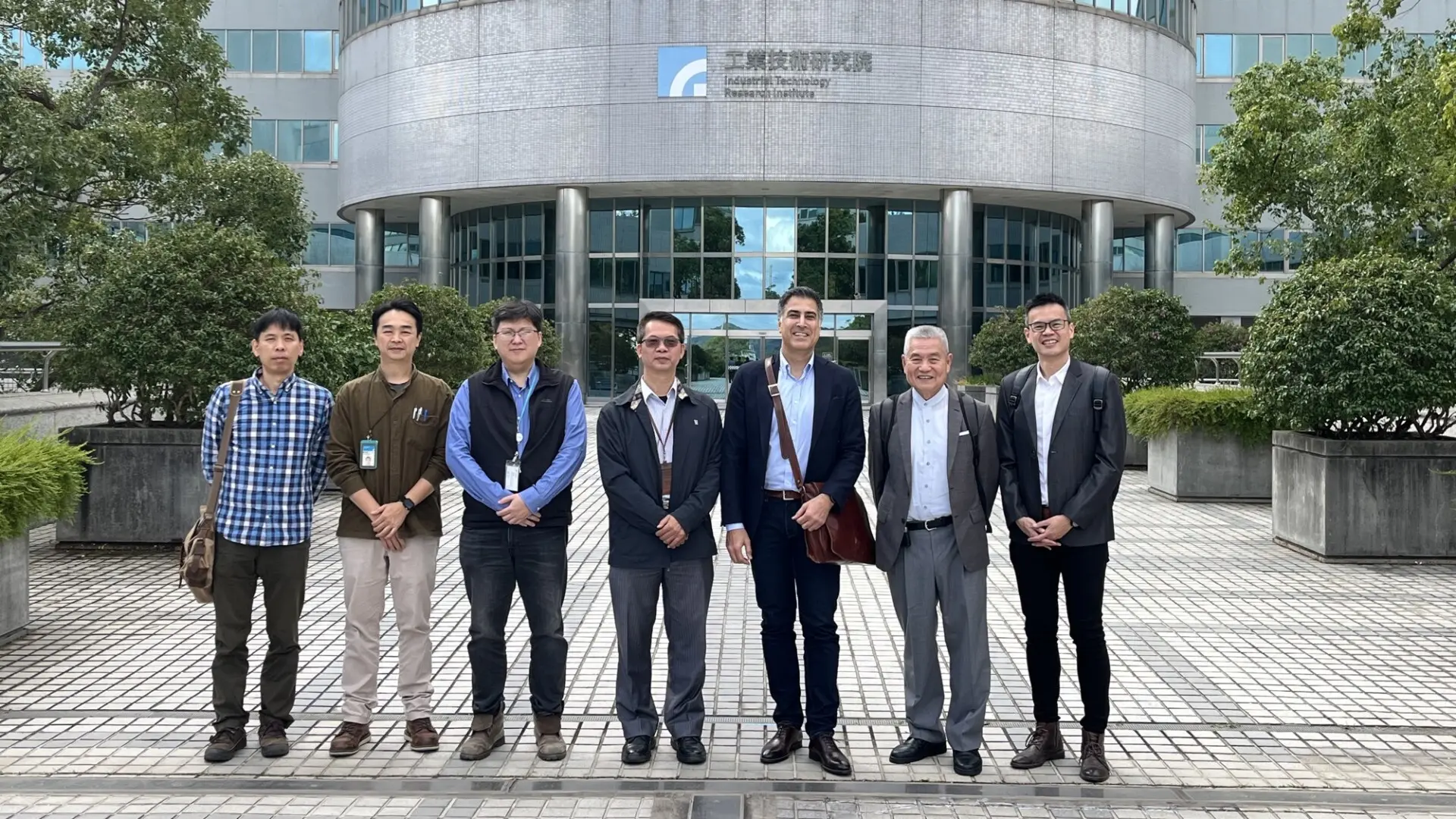

Smoltek Semi has initiated the signing of a technical service agreement with the Taiwanese Industrial Technology Research Institute (ITRI) that enables low-volume production of Smoltek's propriety CNF-MIM capacitors.

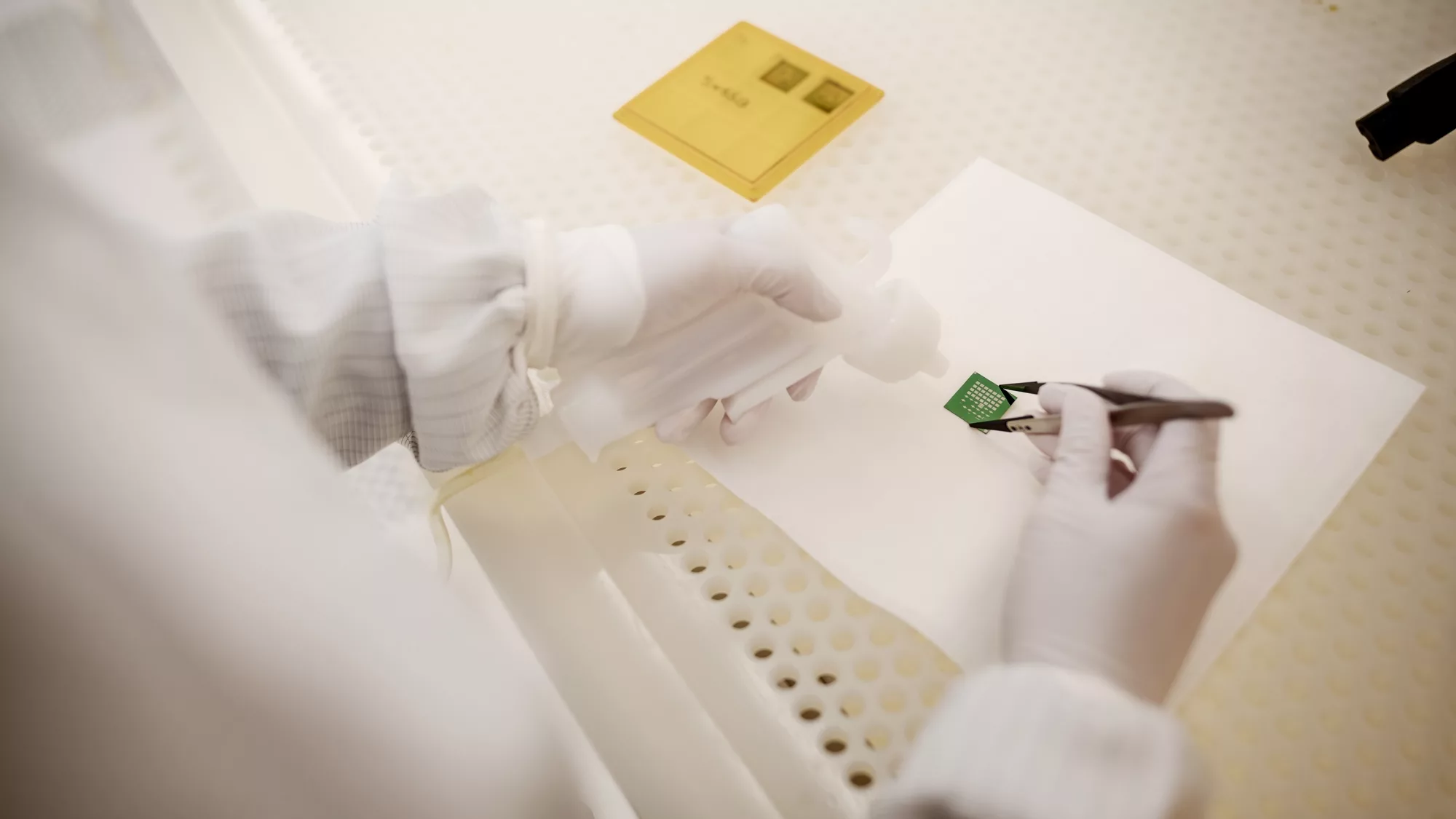

The formal signing process of the agreement, enabling low-volume production of Smoltek’s ultra-thin CNF-MIM capacitors, is expected to be completed within days. As part of the collaboration, Smoltek will install and bring up its advanced CVD tool (carbon nanofiber growth tool) at ITRI. This marks the beginning of the industrialization of Smoltek’s technology for ultra-thin capacitors aimed at advanced processor chips.

“The Technical Service Agreement allows us to accelerate our roadmap and engage more closely with potential customers who require early samples of our high-performance, ultra-thin capacitors.”

Farzan Ghavanini, CTO of Smoltek

The technical service agreement ensures that Smoltek gains seamless access to ITRI’s specialized technical competence and engineering resources—an essential step in preparing for commercial deployment. This arrangement allows the company to refine its processes under industrial conditions while leveraging ITRI’s semiconductor R&D environment.

“Smoltek’s innovative CNF-MIM capacitor technology is highly relevant to the semiconductor industry’s drive for greater miniaturization and performance. By combining our advanced R&D infrastructure and engineering expertise with Smoltek’s unique nanotechnology, we aim to accelerate the path toward industrial adoption.”

Dr. Arthur Lin, Division Director at ITRI’s Smart Sensing & Systems Technology Center

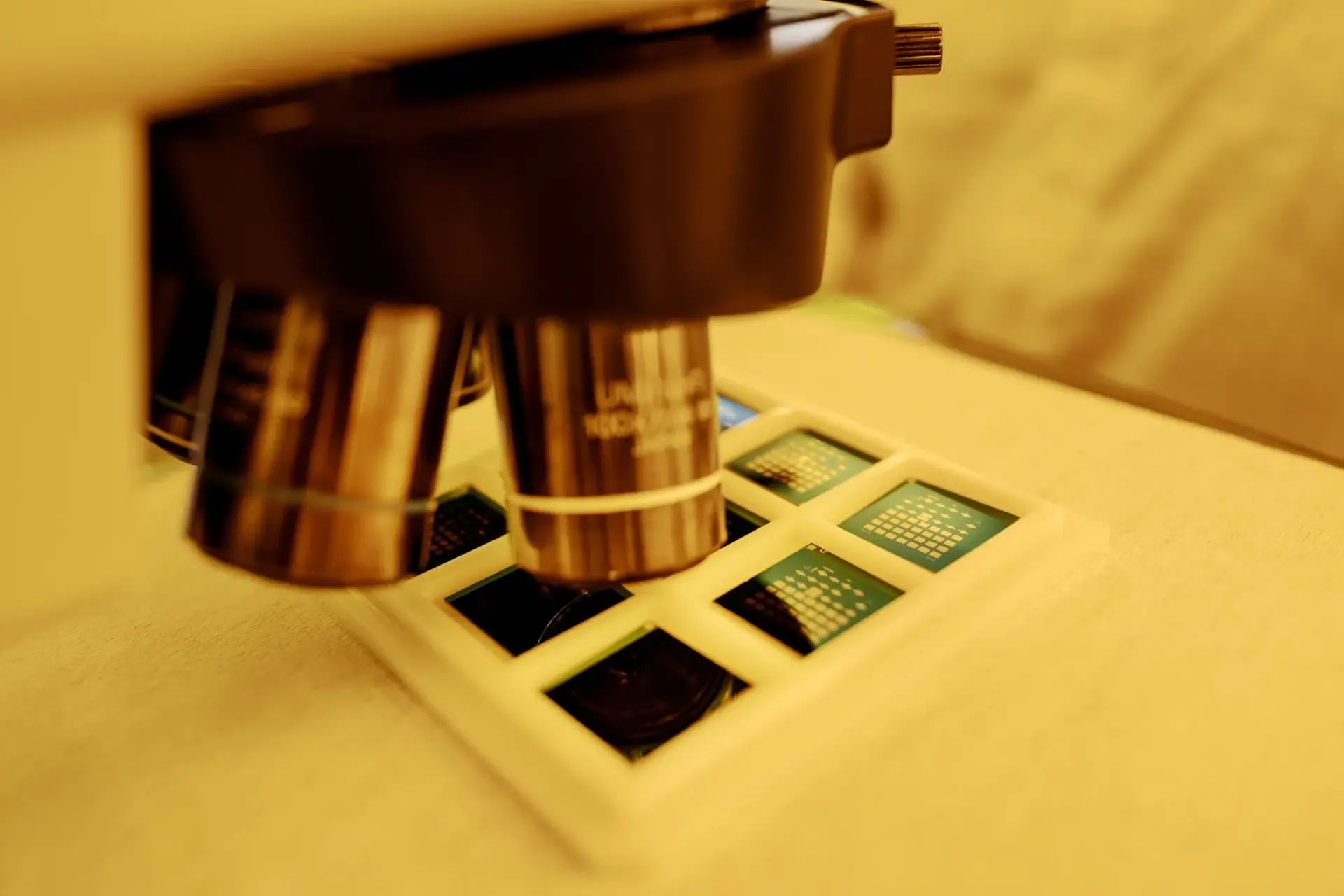

Furthermore, the installation and integration of Smoltek’s custom-designed CVD tool at ITRI’s facilities enables a complete and seamless fabrication process to be carried out in one location. This integrated setup is a critical enabler for small-scale production, as it reduces logistics complexity, shortens development cycles, and ensures tighter process control.

“Having our advanced CVD tool on-site at ITRI gives us access to a complete value chain—from material growth to capacitor integration—in a single location. This is a key milestone toward bringing our technology from lab to fab.”

Magnus Andersson, CEO of Smoltek

Smoltek’s patent protected CNF-MIM™ technology enables the fabrication of extremely thin capacitors with high capacitance density. These are ideally suited for integration in the minimal space beneath advanced processor chips—an area where electrical performance and form factor are both critical. This gives Smoltek’s technology a unique competitive advantage for next-generation devices in mobile, AI, and high-performance computing markets.

Read the official press release here: Smoltek and ITRI Initiate Technical Service Agreement for small scale production of CNF-MIM Capacitors.

Your data will be handled in compliance with our privacy policy.

News

February 24, 2026

An independent, third-party reliability test of our CNF-MIM capacitor technology has confirmed the reliability results communicated on February 5, 2026. The independent validation, performed by a major capacitor manufacturer, also reduces technical risk in the commercialization process and strengthens Smoltek’s credibility in ongoing negotiations with industrial partners.

News

February 5, 2026

Smoltek’s CNF-MIM capacitors demonstrate excellent stability in a new 1,000-hour life test at 85°C under applied 2 volts. No degradations were observed, and the capacitors exhibited more than 1,000 times lower current leakage compared to the previous life test.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 17, 2025

Smoltek Semi is currently optimizing the company’s advanced PECVD system to ensure implementation of its most recent technological innovations in CNF synthesis, enabling compliance with stringent customer requirements, prior to installation at ITRI in Taiwan.

News

November 5, 2025

Smoltek Semi has reached an important technical milestone in the development of the company’s carbon fiber-based CNF-MIM technology. The capacitors have successfully passed a 1,000-hour high-temperature durability test, confirming the robustness of the technology for advanced applications.

News

October 24, 2025

Smoltek Semi has acquired a plasma-enhanced Atomic Layer Deposition (ALD) system to implement its advanced dielectric stack on carbon nanofibers. The system will significantly reduce the iteration time of coating processes while enabling innovation and IP generation in dielectric stack technology for carbon nanofiber electrodes.