Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

During the year Smoltek has installed two new equipment systems for enhancing the R&D work. This will give the company long-term benefits with increased opportunities of technology development and cost efficiency.

Smoltek has invested in a new CVD-system for more effective and versatile growth of carbon nanostructures. The completion of the installation and subsequent commissioning of our new CVD-system to our research lab at Chalmers MC2-building allows us to increase our CNF-MIM R&D capacity, making it possible to produce our CNF-MIM prototype capacitors on 150 mm wafers.

Furthermore, the addition of the new CVD-system provides the necessary redundancy and process reproducibility in order to meet the increasing number of customer requests in terms of proof-of-concept and prototypes. This applies to semiconductors as well as to the development of new technology applications in the field of energy conversion and energy storage (ie. electrolyzers and fuel cells).

R&D engineer Amin Saleem has made the first growth in this new system – a 150 mm wafer filled with CNF-MIM capacitors

New measurement system

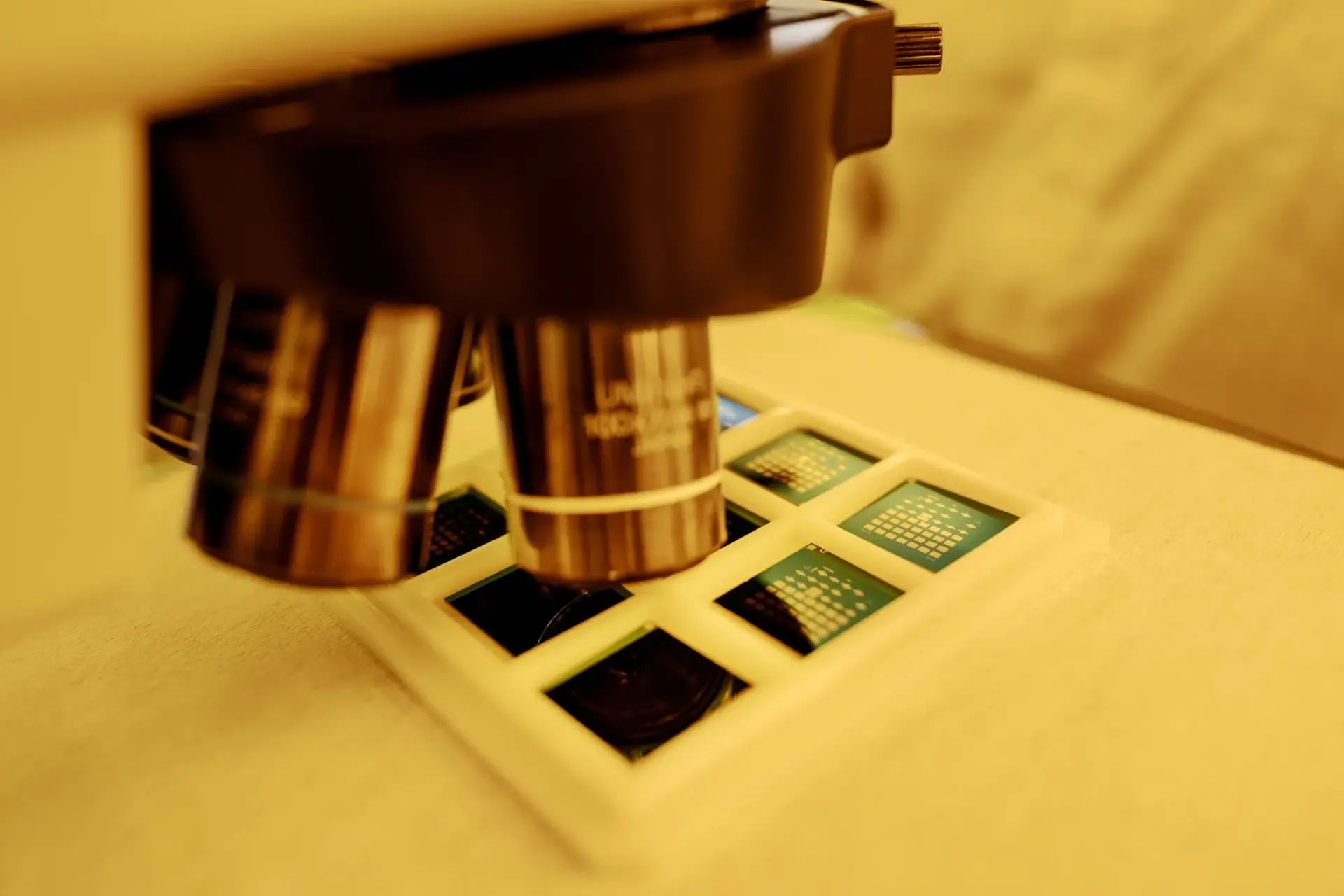

Smoltek has also invested in a new measuring instrument system, which provides increased possibilities, not only for measuring and electrically characterizing of different prototypes, but also assess the time and temperature stability and reliability of our devices. The investment will further increase the opportunities and cost efficiency of technology development.

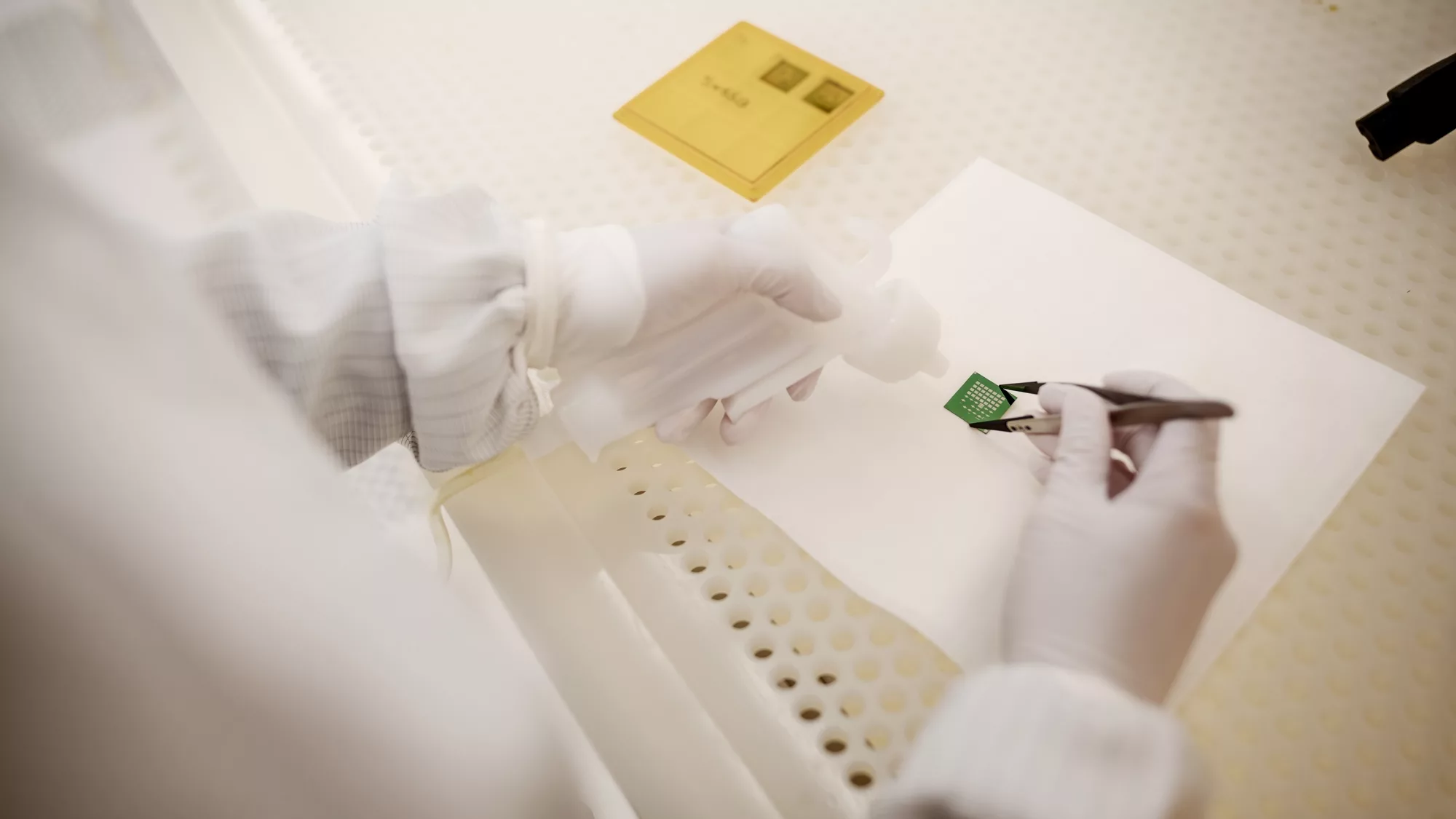

R&D engineer Victor Marknäs characterizing CNF-MIM samples

“We will benefit greatly from this expanded measurement capacity where we can, for example, perform reliability tests and have a more dedicated measurement setup for CNF-MIM capacitors. For all samples we produce, several parameters need to be characterized, such as frequencies, leakage current, voltage dependence, temperature dependence and so on,” says Victor Marknäs, R&D engineer at Smoltek.

Top image: R&D engineers at Chalmers MC2 laboratory

Your data will be handled in compliance with our privacy policy.

News

February 24, 2026

An independent, third-party reliability test of our CNF-MIM capacitor technology has confirmed the reliability results communicated on February 5, 2026. The independent validation, performed by a major capacitor manufacturer, also reduces technical risk in the commercialization process and strengthens Smoltek’s credibility in ongoing negotiations with industrial partners.

News

February 5, 2026

Smoltek’s CNF-MIM capacitors demonstrate excellent stability in a new 1,000-hour life test at 85°C under applied 2 volts. No degradations were observed, and the capacitors exhibited more than 1,000 times lower current leakage compared to the previous life test.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

News

November 17, 2025

Smoltek Semi is currently optimizing the company’s advanced PECVD system to ensure implementation of its most recent technological innovations in CNF synthesis, enabling compliance with stringent customer requirements, prior to installation at ITRI in Taiwan.

News

November 5, 2025

Smoltek Semi has reached an important technical milestone in the development of the company’s carbon fiber-based CNF-MIM technology. The capacitors have successfully passed a 1,000-hour high-temperature durability test, confirming the robustness of the technology for advanced applications.

News

October 24, 2025

Smoltek Semi has acquired a plasma-enhanced Atomic Layer Deposition (ALD) system to implement its advanced dielectric stack on carbon nanofibers. The system will significantly reduce the iteration time of coating processes while enabling innovation and IP generation in dielectric stack technology for carbon nanofiber electrodes.