Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

News

February 5, 2026

Smoltek’s CNF-MIM capacitors demonstrate excellent stability in a new 1,000-hour life test at 85°C under applied 2 volts. No degradations were observed, and the capacitors exhibited more than 1,000 times lower current leakage compared to the previous life test.

IR Blog Posts

December 19, 2025

Some years ago, in three articles, I outlined a vision where nanomaterials in general, and Smoltek’s proprietary nanotechnology platform in particular, would help in breaking barriers in several industries – especially in the semiconductor industry – bringing more supersmart gadgets to society.

IR Blog Posts

December 17, 2025

Artificial intelligence (AI) is the collective term for technologies that enable computers to perform tasks that normally require human intelligence – such as recognizing images, understanding language, playing games or making decisions. It is based on algorithms, mathematical models and (now mainly) Machine Learning and Deep Learning, where neural networks are trained on large data sets.

IR Blog Posts

December 12, 2025

Smoltek conducts advanced research and innovation based on nanotechnology to develop new material technology opportunities that can solve many of today's industrial challenges. This journey began 20 years ago, when Dr. Shafiq Kabir, together with David Brudö and Dr. Peter Enoksson, founded the company.

News

November 20, 2025

We have launched a podcast about materials technology and investments in general and our disruptive carbon nanotechnology in particular.

IR Blog Posts

November 20, 2025

In the first ”Smoltalk” podcast, CEO Magnus Andersson is joined by Smoltek Semi CTO Dr. Farzan Ghavanini for a technical deep dive. Dr. Ghavanini discusses the core CNF-MIM technology in detail, covering everything from its unique material properties and AI applications to the complete product roadmap, key partnerships, and future integration plans. This article summarize the highlights of the conversation.

News

November 17, 2025

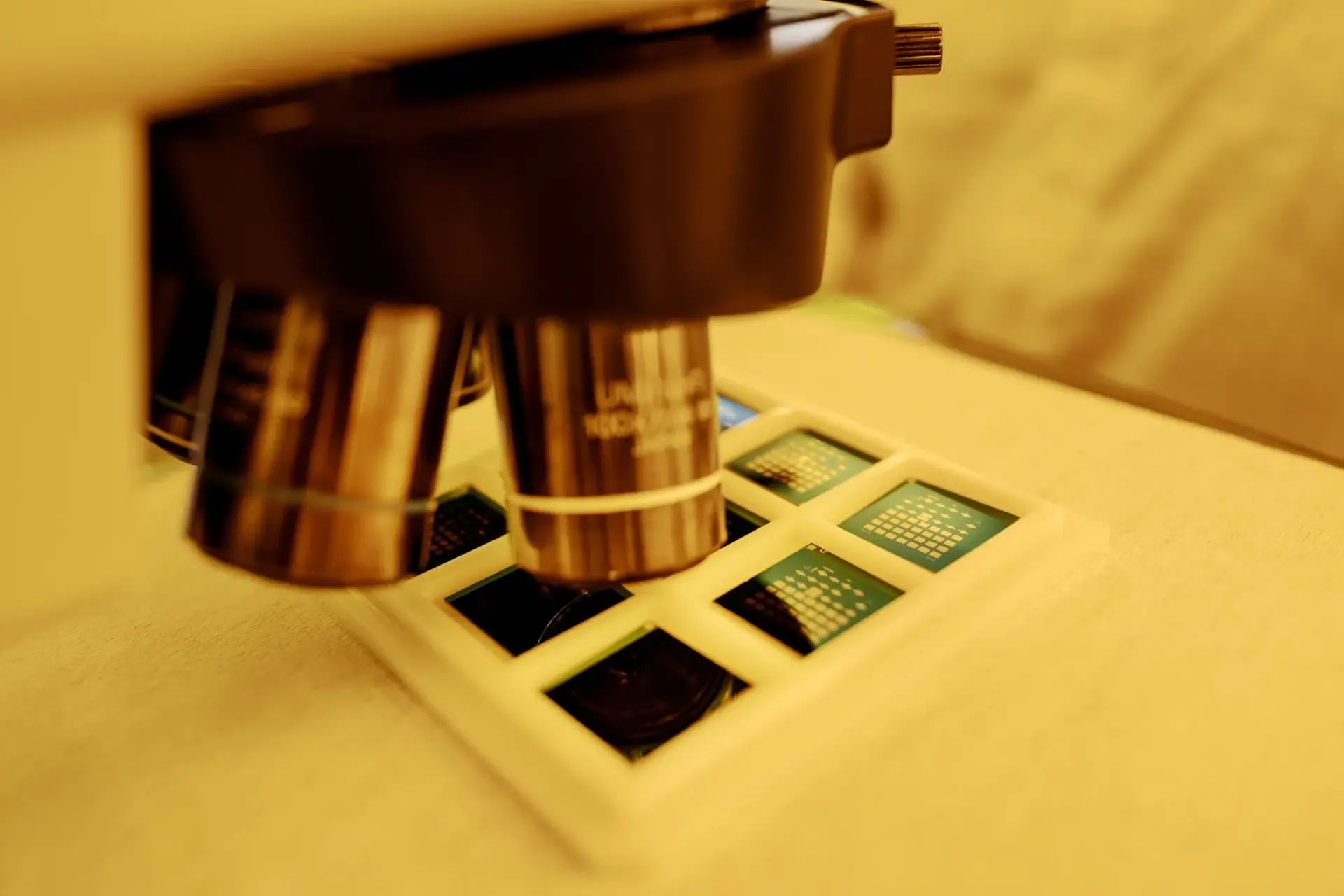

Smoltek Semi is currently optimizing the company’s advanced PECVD system to ensure implementation of its most recent technological innovations in CNF synthesis, enabling compliance with stringent customer requirements, prior to installation at ITRI in Taiwan.

News

November 5, 2025

Smoltek Semi has reached an important technical milestone in the development of the company’s carbon fiber-based CNF-MIM technology. The capacitors have successfully passed a 1,000-hour high-temperature durability test, confirming the robustness of the technology for advanced applications.

News

October 24, 2025

Smoltek Semi has acquired a plasma-enhanced Atomic Layer Deposition (ALD) system to implement its advanced dielectric stack on carbon nanofibers. The system will significantly reduce the iteration time of coating processes while enabling innovation and IP generation in dielectric stack technology for carbon nanofiber electrodes.

News

September 17, 2025

Smoltek Semi has successfully participated in Semicon Taiwan 2025, invited by their strategic partner ITRI.

News

September 10, 2025

Smoltek Semi is selected by ITRI, as one out of three collaboration partners, to be part of their exhibition stand at Semicon Taiwan 2025. We are grateful to be able to present our ultra-thin CNF-MIM capacitor technology for powering next generation advanced semiconductor chips.

News

June 27, 2025

Smoltek Semi has cleared a significant milestone in the development of next-generation CNF-MIM capacitors. Samples from the latest prototype generation, fabricated with an advanced dielectric stack composed of zirconium oxide (ZrO₂) and aluminum oxide (Al₂O₃) have demonstrated exceptional stability under both temperature and voltage stress.