Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

Discover how Smoltek’s innovative Porous Transport Electrode (PTE) technology stands up to expert scrutiny. Learn about its impressive performance, and why it’s poised to transform PEM electrolyzers. Get the inside scoop on what this means for Smoltek’s future in the green hydrogen market.

Smoltek Hydrogen has received an order to carry out a small preliminary study of a special type of electrochemical cell, adapted for electronic devices. This could open new business opportunities for Smoltek.

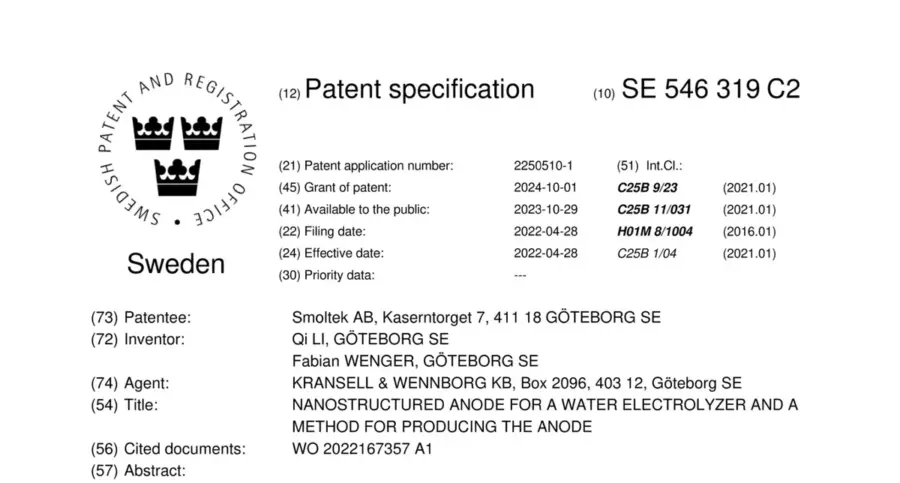

Smoltek has been awarded a new patent within the hydrogen business area. The patent discloses an invention for corrosion protection of nanostructures with non-noble metal oxides on the anode in PEM water electrolysis, improving the durability and efficiency of electrodes with low iridium loading.

The Electrolyzer Oxide Coating family offer a chemically stable solution, coating a nanostructure with non-noble metal oxides, this avoiding the use of expensive platinum for anode porous transport electrodes (PTEs). The inventions also improve the durability and efficiency of the PTE.

Smoltek is a Gothenburg-based materials technology company that specializes in research and development of applications based on carbon nanofibers, which can create new products with revolutionary properties.

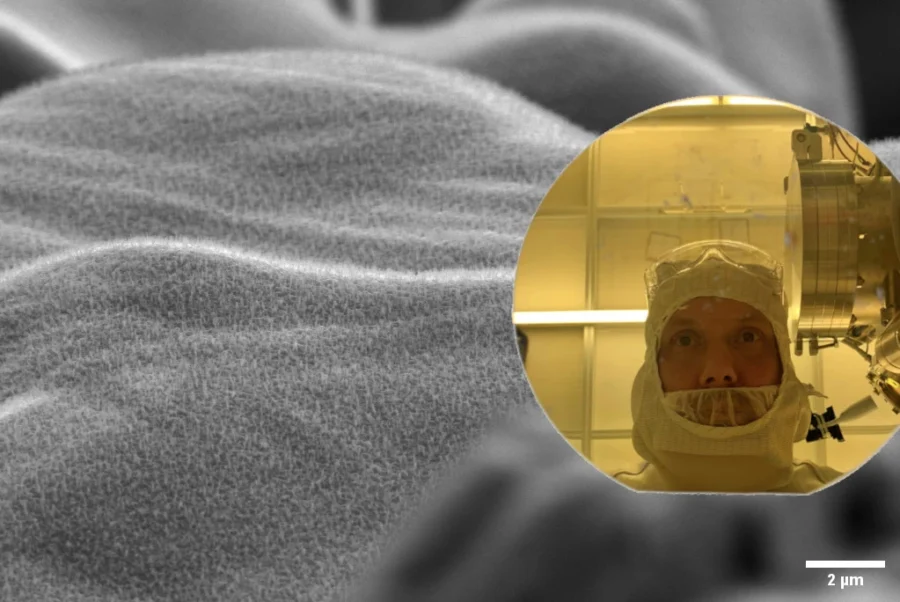

Smoltek Hydrogen has made a significant technological breakthrough. The R&D team has successfully grown carbon nanofibers (CNFs) over an A4-sized area, marking the first time such a large CNF-covered material sample has been fabricated. This breakthrough is a crucial step towards industrial scalability of carbon nanofiber coating, which is a key step in developing the porous transport electrode for PEM electrolyzers and similar solutions for fuel cells being developed by Smoltek Hydrogen.

During the spring, we have had John Schack, a master’s thesis student, with us at Smoltek Hydrogen who has been working on the synthesis of carbon nanofibers (CNF) – where we have adjusted the growth recipe to use hydrogen as input instead of ammonia.

Towards scalability of industrial carbon nanofiber growth: The development of the industrial manufacturing concept for Smoltek Hydrogen’s Electrolyzer Cell Material is at its final stages, with aim on being finalized during 2024. As a stepping stone, the capability in the company’s existing Plasma Enhanced Chemical Vapor Deposition (PECVD) tool has been extended and A4 size plasma has been achieved. This is a crucial step towards industrial scalability of carbon nanofiber growth.

Smoltek Hydrogen has developed a new material that solves the major technical challenge that threatens to halt the fast-growing industry for green hydrogen produced by intermittent energy sources, such as solar and wind power. With the groundbreaking nanomaterial, the use of iridium (catalysts) in PEM electrolyzers can be reduced to levels that make large-scale hydrogen production profitable.

Ellinor Ehrnberg, CEO of Smoltek Hydrogen, is interviewed in a popular podcast. She is asked about her career, the current challenges facing the hydrogen industry, how Smoltek Hydrogen is solving them and the company's future plans. You won't want to miss this! Read the summary and listen to the podcast.

Smoltek Hydrogen and AGC Plasma Technology Solutions have finalized the design of a Prototype Coater for industrial growth of carbon nanofibers. The purpose with the tool is to verify that the nanofibers can be grown using a Plasma Enhanced Chemical Vapor Deposition (PECVD) technology from AGC. The technology is scalable and can be extended to be used for substrates of several square meters, for future mass production.

One of the world's largest vehicle manufacturers is testing custom-made prototypes of a cell material that can significantly reduce the amount of iridium in an electrolyzer cell. The custom-made prototypes delivered by the subsidiary Smoltek Hydrogen have the potential to reduce the iridium load in electrolyzer cells by 95% compared to today's commercial materials, which is a prerequisite for large-scale production of fossil-free hydrogen.