Sign up for our newsletter!

Your data will be handled in compliance with our privacy policy.

Your data will be handled in compliance with our privacy policy.

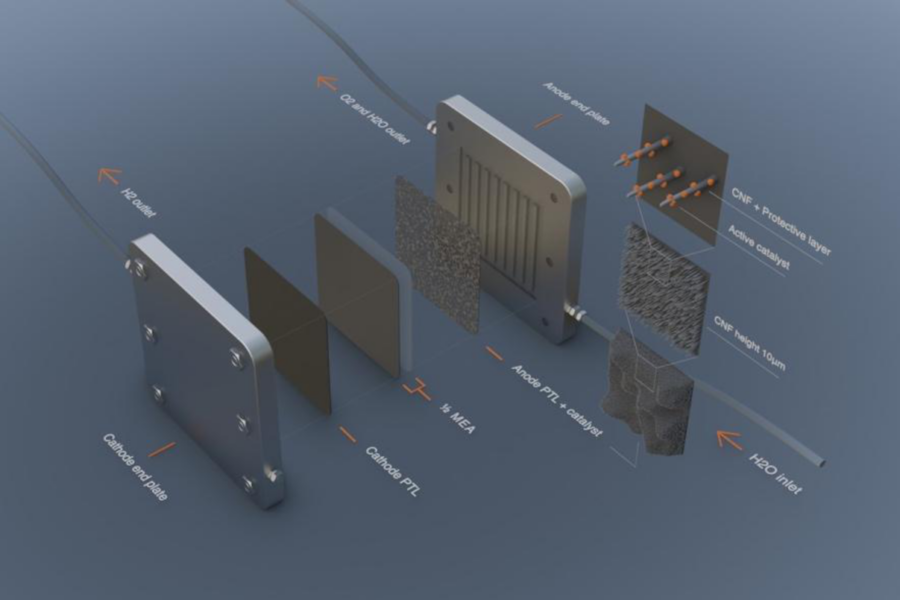

Smoltek Hydrogen has formed a strategic collaboration with Impact Coatings to assess the industrialization of Smoltek’s carbon nanofiber (CNF) technology for use in PEM electrolyzers and fuel cells.

Smoltek Hydrogen notice a strong interest from global industrial companies within PEM electrolyzers and fuel cells regarding our disruptive PTE-technology. Driven by the realization that early adoption provides crucial competitive advantages, there are now several hydrogen giants that are evaluating the technology.

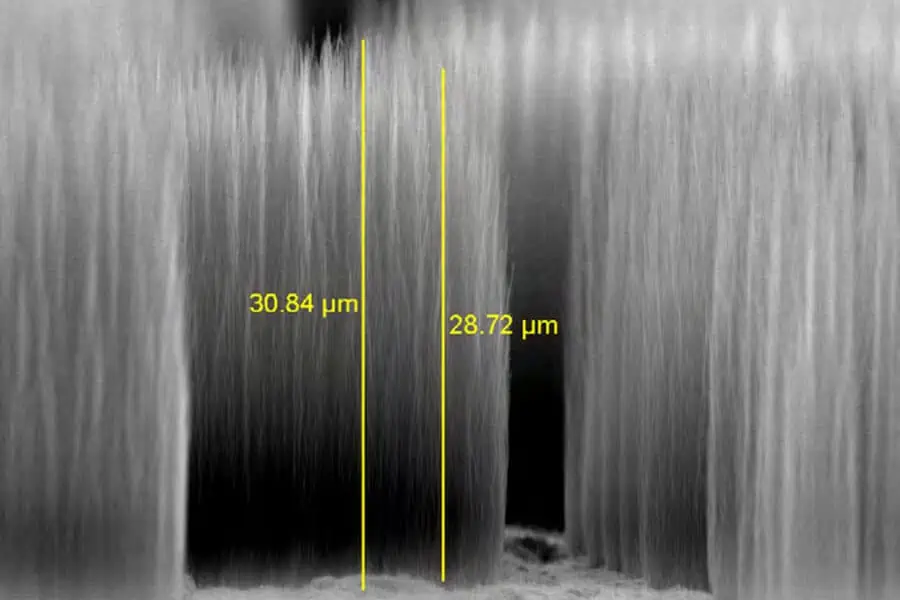

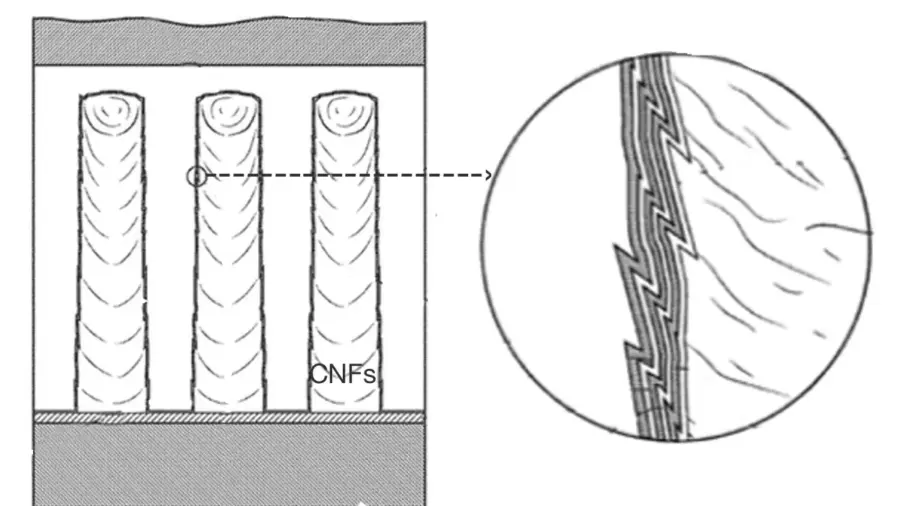

Smoltek's nanofibers dramatically increase catalytic activity for ultra-low-iridium electrolysis enabling more cost-effective green hydrogen production.

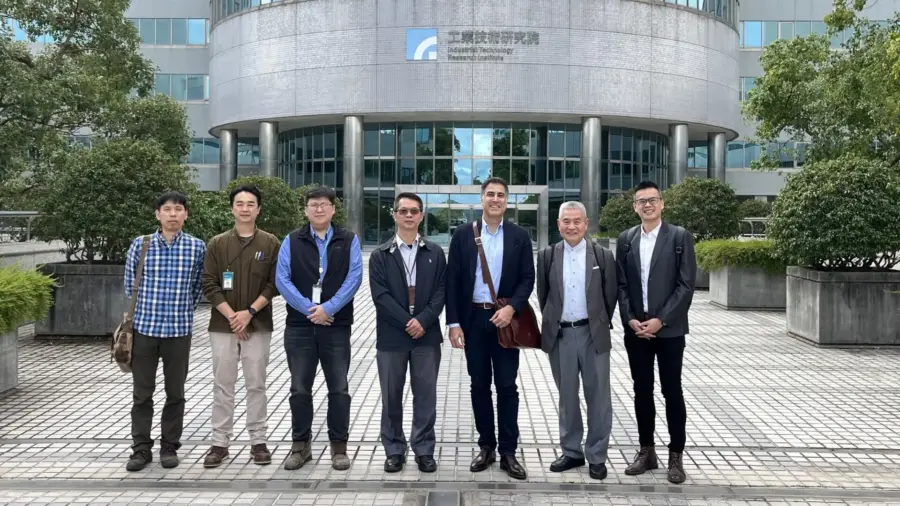

Smoltek Semi and the Taiwanese Industrial Technology Research Institute (ITRI) have finalized the technical framework for the establishment of a pilot production line for Smoltek's CNF-MIM capacitors at ITRI.

Qi Li and ChinJung Kuo of Smoltek Semi have met with Skytech management in Taiwan for planning of testing dummy runs for ALD deposition of Smoltek's CNF-MIM capacitors.

In an age where environmental sustainability is of utter importance, it is crucial to find innovative solutions to reduce energy consumption and minimize our carbon footprint. One such solution is found in capacitors. These unassuming electronic components not only play an important role in various systems, but also offer significant environmental benefits. Albeit very small – if counted one by one.

Smoltek Hydrogen is attending the 247th ECS Meeting in Montréal, Canada. The event brings together the most active researchers in academia, government, and industry to engage, discuss, and innovate in the areas of electrochemistry and solid state science and related technologies.

Smoltek Hydrogen has entered into a strategic collaboration with Heraeus Precious Metals to elevate the functional efficiency of porous transport electrodes in proton exchange membrane (PEM) electrolyzers to new heights.

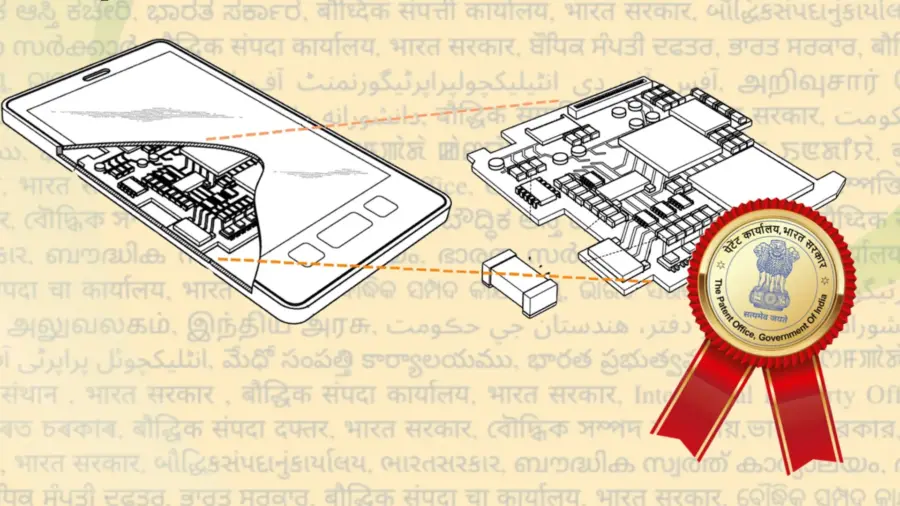

Smoltek is awarded an additional patent in the Discrete CNF-MIM patent family. The protected innovation in this patent family discloses a discrete capacitor component based on our CNF-MIM technology. This also brings our IP portfolio to comprise 94 granted patents.

Smoltek Hydrogen is attending WISE Dialogue meeting 2025, in Münchenbryggeriet, Stockholm, and we are participating in the poster session, to showcase our progress towards minimizing the iridium load in electrodes (PTEs) for PEMWE.– to just 0.1 mg/cm2.

Smoltek has been awarded another patent in the Multilayer Cap patent family. The innovation in this patent family introduces a MIM-capacitor device that can double or triple the capacitance density of our CNF-MIM capacitors.

Smoltek Hydrogen has produced hydrogen with only 0.1 mg of iridium per square centimeter in a 250-hour durability test – making our PTE a breakthrough technology for PEM electrolyzers.

We are pleased to announce that the new zirconia based dielectric stack, previously reported to show 230% improvement in capacitance density, has now passed the 1,000-hour DC life test, a preliminary reliability test, carried out by capacitor manufacturer Yageo.

Dr. Farzan Ghavanini, CTO of Smoltek has been on a week-long business trip to Taiwan to visit some of our collaboration partners for CNF-MIM capacitors, among those ALD-company Skytech.

Leading PEM technology expert Dr. Felix Büchi has completed an independent assessment of Smoltek Hydrogen’s Porous Transport Electrode (PTE) technology, confirming its unique ability to significantly reduce iridium usage while maintaining the same high performance in hydrogen production as conventional technology.

Smoltek recently visited its Taiwanese partner in advanced microelectronic packaging to discuss the specific requirements for next generations of Smoltek's CNF-MIM (Carbon Nanofiber-Metal Insulator-Metal) capacitors.

Smoltek Semi and Taiwanese Industrial Technology Research Institute (ITRI) are discussing a collaboration to set up a pilot line for fabrication of CNF-MIM capacitors in Taiwan as part of getting ready for mass production.

Interview with Philip Lessner, CTO of Yageo Group about the rapid development in the capacitor industry, the market evolvement and future technology needs for ultra-thin capacitors. And how CNF-MIM technology fits into this market. This is a follow-up to the interview from earlier this year. Yageo remains interested in Smoltek's CNF-MIM capacitors and sees great potential for using CNF-MIM capacitors in their customer offering.

Smoltek Semi is attending EFECS 2024 meeting in Ghent, Belgium, December 5–6 2024. The conference is arranged by is organised by Chips Joint Undertaking (Chips JU) with the support of the three industry associations Aeneas, EPoSS and Inside.

Smoltek Hydrogen has been invited to participate in a Scandinavian delegation of technology leading hydrogen companies for a round-trip to Germany’s energy-producing regions in Rhur and central Germany.